We are currently building a giant Magnetic Levitation Floor (MaglevFloor, MagFloor) at the University of Waterloo RoboHub. With the use of magnetic energy, artificial intelligence, and advanced control algorithms, our team is building one of the largest levitation platform in the world.

The technology used in MagFloor will advance the manufacturing industry considering its exceptional design, precision, speed, flexibility, and versatility. This system will open new avenues of research in the areas of collaborative robotics, flexible manufacturing, and autonomous systems. The above animation represents the idea behind the MagFloor and its collaboration with other advanced apparatus such as robot arms and humanoid robots.

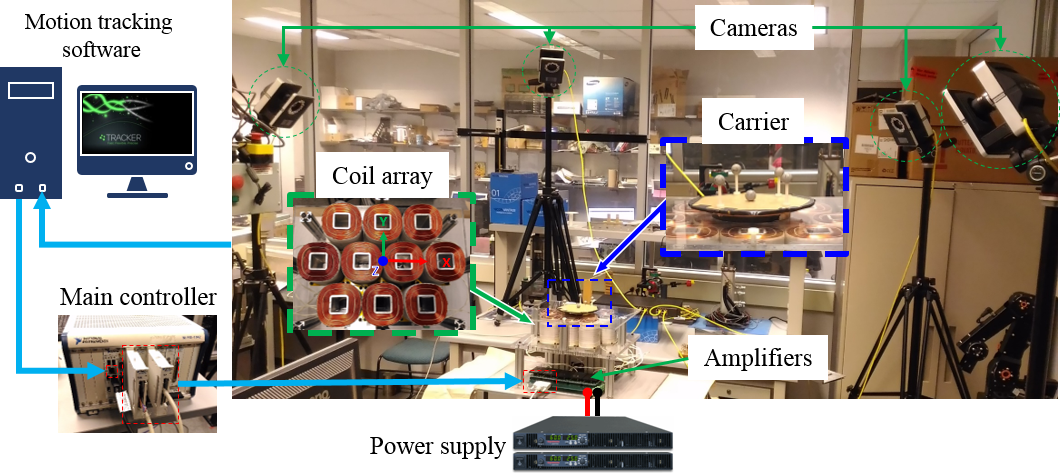

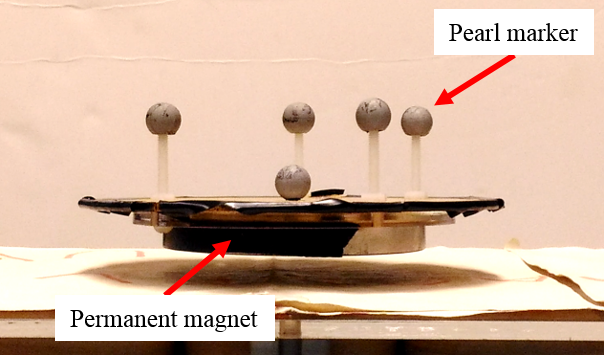

A protype was developed to study the feasibility of the system. With a single disc permanent magnet, the carrier motion could be controlled up to five degrees of freedom. The experiment results demonstrate the great potential of the system. Opportunities for advanced research are available for high-precision motion control, energy consumption optimization, and application of the system in various fields.

List of Publications

- Y. Wang, Z. Xu and M. B. Khamesee, "Magnet-Coil Role-Switching Real-Time Wrench Model for Magnetic Levitated Motors With Extendable Motion Range," in IEEE Transactions on Industrial Electronics, Aug. 2024.

- Y. Wang and M. B. Khamesee, "Deep Learning-Based Wrench Model for Magnetically Levitated Actuators," in IEEE Transactions on Industrial Electronics, Mar. 2024.

- Z. Xu, C. Trakarnchaiyo, C. Stewart, M. B. Khamesee, "Modular maglev: Design and implementation of a modular magnetic levitation system to levitate a 2D Halbach array," in Mechatronics, vol. 99, Feb. 2024.

- Z. Xu, Y. Wang, J. Wang, M. B. Khamesee, "Predictor-based model predictive control for maglev planar motor with a 2D Halbach array mover," in Control Engineering Practice, vol. 141, Oct. 2023.

- C. Trakarnchaiyo and M. B. Khamesee, “A novel wrench–current decoupling strategy to extend the use of small lookup data for a long-range maglev planar motor,” in Actuators, vol. 12, no. 9, Sep. 2023.

- C. Trakarnchaiyo, Y. Wang, and M. B. Khamesee, “Design of a compact planar magnetic levitation system with wrench–current decoupling enhancement,” in Applied Sciences, vol. 13, no. 4, Feb. 2023.

- Z. Xu, X. Zhang and M. B. Khamesee, "Real-time data-driven force and torque modeling on a 2-D Halbach array by a symmetric coil considering end effect," in IEEE Transactions on Magnetics, vol. 58, no. 11, Nov. 2022.

- X. Zhang, C. Trakarnchaiyo, H. Zhang, and M. B. Khamesee, "MagTable: A tabletop system for 6-DOF large range and completely contactless operation using magnetic levitation," in Mechatronics, vol. 77, Jun. 2021.