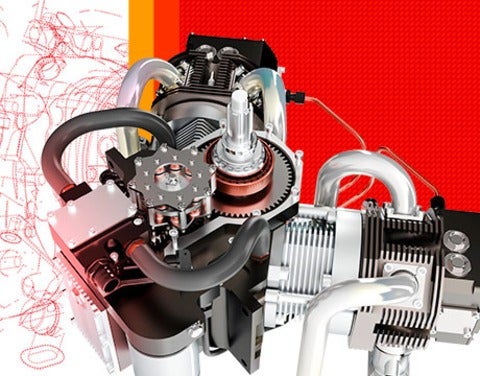

Ellipse-D powering a self-driving truck

We all know that accidents happen on the road mainly because of mistakes by drivers, bad weather, or problems with the vehicle itself. But what if we could make vehicles drive on their own, avoiding these accidents? That’s the idea behind self-driving vehicles, and the University of Waterloo’s Mechatronic Vehicle Systems (MVS) Lab is working on a project called WATonoTruck (WATerloo atonomous Truck). It’s a self-driving flatbed truck designed for heavy material handling, farming, and service applications. It uses advanced control methods to understand how the truck moves, especially in dangerous places or if something in the truck isn’t working right.

The lab aims to extend the application of autonomous vehicle technology beyond passenger transportation. They want to use it in other industries like agriculture, mining, and shipping, thereby increasing efficiency and reducing operational downtime.

Read the full article at SBG Systems.