Background

Encapsulation is very important in a wide range of industry applications including pharma, agriculture and food processing as it protects the core material and safeguards it from an aggressive environment and/or enables timely release of the cargo material to a targeted area.

Conventionally, such protection has been achieved either by creating a thin coating layer of Polymers/Nano-particles/ surfactants/ powders around the core material or by wrapping it in a thin bendable solid polymer sheet. However, in addition to their high cost and intrinsic complexity, existing methods have limitations such as reduced cargo volumes, encapsulating layer(s) thickness control and encapsulating layer(s) functional properties which limits their applicability in pharmaceutical and food processing industry due to lack of precise (quality) control and operational flexibility.

Description of the invention

By exploiting liquid-liquid interfacial energy differences, researchers at the University of Waterloo have invented a simple and low-cost method for accurately encapsulating a liquid core material with a thin liquid film(s) with controllable thickness. The new method allows a wide range of “core-shell” combinations and enables the design of surface-active, multi-layered (liquid/ solid/ colloid) capsules which enables maximum flexibility in designing unique capsules.

Advantages

The invention provides:

- High-speed encapsulation (multilayer encapsulation in milliseconds)

- Simple, compact and low-cost – i.e. does not need expensive infrastructure

- Bio-active material coating/encapsulation

- Nano-particle coating/encapsulation

- Direct encapsulation of liquid materials

- Multilayer coatings at once

- Imparting different characteristics to the final “parcel”

- Multiple core materials can be encapsulated and delivered in the same “parcel”

- Both small- and large-scale manufacturing

Potential applications

- Pharmaceuticals (targeted drug delivery/ delayed release of multiple active components in a single “parcel”)

- Nutraceuticals

- Agriculture

- Food and confection processing

- Cosmeceuticals and personal care products

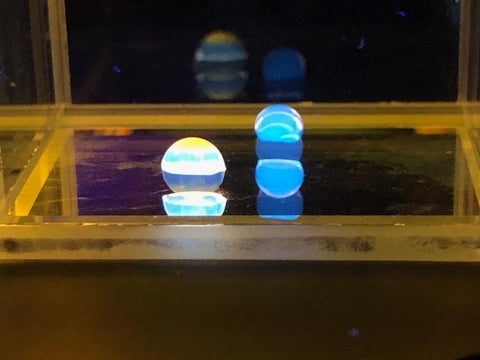

Unencapsulated drop of liquid on the right and encapsulated drop on the left

Prototyped Encapsulation Machine

Reference

10151

Patent status

Patent pending

Stage of development

Prototype built and tested

Ongoing research

Contact

Scott Inwood

Director of Commercialization

Waterloo Commercialization Office

sinwood@uwaterloo.ca

uwaterloo.ca/research