Background

Gear shaping is one of the most prominent methods for manufacturing cylindrical gears. It is highly versatile and is one of the only processes capable of machining internal gears.

None of the currently available simulation software programs take into account all of the important factors affecting the quality of a machined gear, such as process kinematics and physical attributes of cutting process (i.e. cutting forces and elastic deflections). As such, existing solutions either have very limited accuracy that leads to limited quality of the machined part or; are extremely slow and not suitable for simulating the entire machining process (e.g. Finite Element Methods approach).

Description of the invention

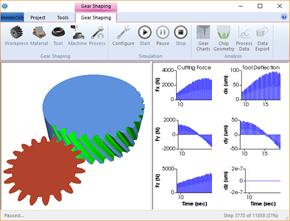

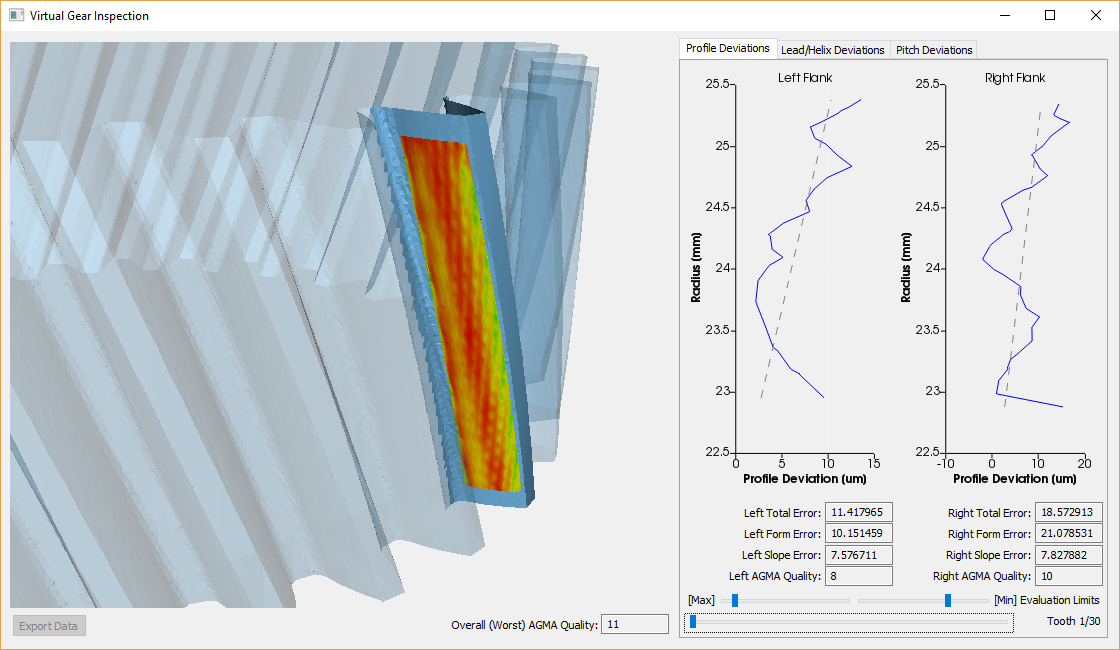

Researchers at the University of Waterloo have combined their deep gear shaping knowledge and years of machining expertise together to develop a machining simulation software called “Digi-Shape” for gear shaping. The software is capable of simulating effects caused by cutting forces and elastic deflections, in addition to the kinematic effects, which greatly improves the accuracy of the predicted quality of the gear. Digi-Shape is the first physics-based software developed specifically for simulating a gear shaping process in its entirety.

Advantages

Digi-Shape allows process planners to virtually manufacture their gears and optimize their process designs offline and without wasting valuable machine time and material. Some of Digi-Shape advantages are:

- Fast off-line simulation – simulates the entire process in minutes.

- Ease of use – databases of workpiece raw material and machining equipment parameters can be added.

- Reduced level of needed expertise for machine operators.

- Cost Saving – eliminates or reduces trial & error process design (thus saves machine idle time, operator time and amount of generated waste) and extends cutting tool/machine lifetime.

- Up to 25~30% productivity increase – In case studies performed by an industrial partner, Digi-Shape reduced trial & error in setting-up new gear shaping process and offered the optimal process parameters for gear shaping machines and cutting tools. The overall productivity increase was measured at 25~30% for shaping of high volume internal gears.

Potential applications

Digi-Shape optimizes gear-shaping process in manufacturing internal and external gears.

A. Digi-Shape user interface

B. Virtual gear metrology module

Reference

10129

Availability status

Non-exclusive license is available

Stage of development

Software developed and tested

Ongoing research

Contact

Scott Inwood

Director of Commercialization

Waterloo Commercialization Office

519-888-4567, ext. 33728

sinwood@uwaterloo.ca

uwaterloo.ca/research