Background

Graphene’s remarkable conductive and physical properties (high elasticity and mechanical strength for instance) are being explored for use in a wide variety of applications including electronic devices, energy storage (batteries, supercapacitors), solar cells, and new conductive and strong composite materials. However, the widespread use of graphene has been limited by the high cost of producing mono-few layers of graphene material using existing techniques such as epitaxial growth, thermal exfoliation of graphite oxide, gas phase synthesis and chemical reduction of graphene oxide, and micromechanical cleavage (MMC) of graphite. Ultrasonification of graphite in the presence of non-volatile solvents is an MMC technique that has been demonstrated to be a simple process that leads to stable dispersions of sub-micrometer graphene crystallites and amenable to mass production for industry applications. However, the use of non-volatile organic solvents requires higher temperatures and costs to remove the solvent from the formed graphene sheets. Even after this expensive high-temperature heat annealing, typically there are organic compounds fixed within the graphene material that impart undesirable quality and performance problems.

Description of the invention

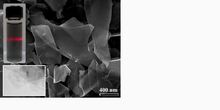

Waterloo researchers have developed an ultrasonification graphite exfoliation process that uses a commonly available and environmentally friendly biopolymer solution that produces a dispersion of graphene sheets with 5-10 layer thickness with very low defect concentration and that exhibit electrical conductivity that is up to 20 times higher than that produced from the more conventional reduction from graphite oxide by Hummer’s method.

Advantages

The process is simple, environmentally friendly, and with 5 wt.% high yield (likely higher with optimization) leading to the possibility of a scalable process for mass production of graphene. The graphene produced from this process is estimated to be approximately 0.03 $/g, while the commercial graphene is being sold in the 20-30 $/g range.

Potential applications

- Conductive polymer composites (eg. automotive applications)

- EMI/RFI shielding

- Energy storage devices (eg. batteries, Supercapacitors)

- Solar Cells

Reference

8810-7352

Inventor(s)

Aiping Yu

Victor Chabot

Zhongwei Chen

Patent status

Issued US 9,527,745 and PCT # PCT/CA2013/051007 and Canada 2,934,099 applications

Stage of development

Testing for conductive composite and electrochemical storage prototypes

Ongoing research

Contact

Scott Inwood

Director of Commercialization

Waterloo Commercialization Office

519-888-4567, ext. 43728

sinwood@uwaterloo.ca

uwaterloo.ca/research