Background

Asphalt cement is an integral part of road network, and it is estimated that by 2050, 25 million kilometers of roads will be constructed globally, of which 90% uses asphalt cement as the binding agent. Asphalt mix is a construction material that uses asphalt cement (bitumen) to bind granular material particles. In this process, all ingredients must be heated to 150-180°C in asphalt mix plants and kept hot during transportation to ensure effective compaction. This process consumes a significant amount of energy and releases harmful gases. Thus, it is essential to explore solutions that can lower processing temperatures to reduce emissions.

One solution is the emulsification of asphalt cement, which allows for the preparation of cold mix asphalt with a lower environmental impact, higher energy savings (up to 90%), and greater cost-effectiveness. Asphalt emulsions are a mixture of asphalt and water stabilized by an emulsifier. However, a major drawback is that the engineering properties of cold mixes are often not satisfactory for most applications, limiting their use to low-volume roads and maintenance activities. Additionally, current emulsifiers typically rely on non-renewable resources.

Description of the invention

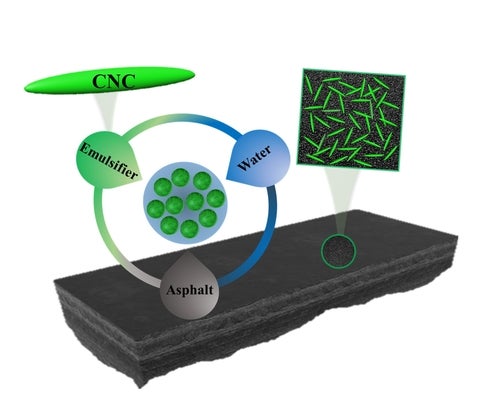

Researchers at the University of Waterloo have developed an innovative asphalt emulsifier using cellulose nanocrystals (CNCs), a renewable material derived from plant biomass. This new emulsifier displays superior performance compared to current surfactant-based technologies. CNCs are amphiphilic particles that form a solid barrier around small oil droplets in water yielding a stable Pickering emulsion of asphalt.

Advantages

Asphalt emulsified with CNC with this method, exhibits superior stability across various temperatures and flow conditions. Rheological analysis, including Dynamic Shear Rheometer (DSR) tests, has shown significant improvements in the viscoelastic behavior and enhanced resistance to permanent deformation during multiple stress creep recovery tests. Mechanical properties of the cured product have also been examined and significant crack resistance improvement was observed. Compared to surfactant-based asphalt emulsions, CNC asphalt emulsions offer greater performance, including improvements in durability, emulsion stability, mechanical properties, aging resistance, and resistance to fatigue damage and cracking, depending on the specific formulation.

Potential applications

- Road works (Fog Seal, Micro surfacing, Cold recycling, …)

- Road repairs (Cold patches, crack sealing)

- Waterproofing

- Dust palliation

- Insulation

CNC application in asphalt emulsion

Reference

10261

Patent status

Patent filed

Stage of development

Prototype has been validated in a simulated (or lab) environment

Contact

Scott Inwood

Director of Commercialization

Waterloo Commercialization Office

sinwood@uwaterloo.ca

uwaterloo.ca/research