Design team members: Bernice Chan, Mark Hopson, Philip Lee, Mike Spendlove

Supervisor: Prof. Roydon Fraser

Background

Ulaanbaatar (UB), the capital of Mongolia, is also the world's coldest capital city, with a 9 month winter averaging below -20 degree Celsius. The country is relatively under-developed, however UB is experiencing rapid industrialization with the expansion of automobile transportation and coal power plants that provide centralized heating. As hundreds of thousands of Mongolians migrate to cities to benefit from the increased opportunities, a shortage of affordable housing units has left many living in gers (or yurts) in the outskirts of urban centres like UB. Although the tent-like ger structures are ideal for the traditional Mongolian nomadic lifestyle, they're not well suited to long term settlement, since the ger walls have poor insulation and require significant heating throughout the winter. In most cases, gers are heated by coal-powered stoves that use low-quality fuel and rarely achieve complete combustion, leading to the production of harmful emissions and greenhouse gasses. These emissions, coupled with automobile exhaust, and power plant pollution, have led to severe problems in air quality both inside gers and in the region.

Studies performed by the World Bank have shown that the average concentration of indoor air pollutants in ger households well exceed World Health Organization standards. A strong statistical correlation exists between poor indoor air quality and respiratory disease. It is the leading cause of child morbidity and mortality, and the fifth leading cause of death in Mongolia.

Extensive attempts have been made to improve coal stoves; results, however, have been marginal with respect to improving indoor air quality. Little research has been performed in addressing socio-cultural factors such as the human interaction with the stove, which may be a large factor affecting indoor air quality.

Project Description

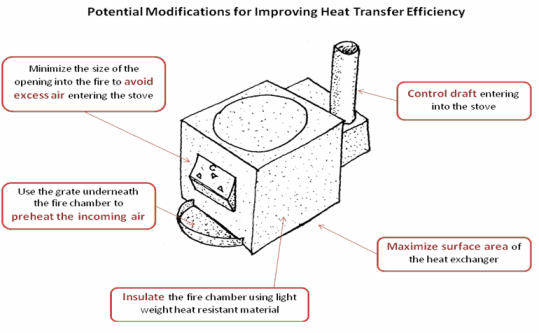

In the ger districts of Ulaanbaatar, the poor heating efficiency of common coal stoves results in wasteful coal use and the excessive release of harmful emissions into the air. This in turn has lead to poor indoor air quality in gers and many associated health problems. The purpose of this design project is to build and analyze a stove model currently used in gers in Ulaanbaatar, and to identify and test potential modifications that could improve the stove's heating efficiency. The design goal will be to improve the stove's heating efficiency in terms of heat released per kg of fuel, however overall project success will also take into account the accumulated research and stove testing results, with regards to their value in future work addressing indoor air quality in Ulaanbaatar.

Design methodology

1.

Root

Cause

Analysis

Although

the

problem

of

poor

indoor

air

quality

in

the

ger

districts

of

Ulaanbaatar,

and

the

associated

health

issues,

have

been

well

identified

in

previous

studies,

the

exact

causes

of

this

pollution,

and

the

relationship

between

the

causes,

are

far

from

certain.

Hence,

in

order

to

better

understand

the

inherent

nature

of

this

problem,

the

team

performed

a

root

cause

analysis

to

iteratively

question

and

assess

the

causes

of

poor

indoor

air

quality

in

a

ger

household.

2.

Problem

definition

&

selection

As

a

team

of

Canadian

students,

it

is

important

to

recognize

the

uncertainties,

limitations

and

challenges

in

addressing

an

international

development

problem.

In

order

to

ensure

that

our

work

in

Canada

can

be

of

value,

that

it

is

appropriate

to

the

living

conditions

of

Mongolians,

and

that

the

selected

problem

is

within

reasonable

scope

of

this

design

course,

a

set

of

selection

criteria

has

been

developed

to

clearly

identify

a

single,

feasible

and

effective

focus

for

the

project,

that

of

studying

and

improving

stove

heating

efficiency.

3.

Testing,

design

&

recommendations

With

the

initial

research

complete

and

the

specific

focus

of

the

project

identified,

the

design,

construction

and

testing

phase

of

the

project

begins.

The

first

step

is

to

develop

a

robust

testing

methodology

for

stoves

to

measure

heating

efficiency,

drawing

on

successful

projects

done

in

the

past,

while

staying

focused

on

the

project

goals.

The

second

step

is

to

build

a

prototype

model

of

a

Mongolian

coal

stove,

the

TT-03,

based

on

design

plans

and

instructions

provided

by

the

World

Bank.

Following

initial

testing

of

the

stove,

an

analysis

of

its

features

and

potential

areas

of

improvement

is

next,

culminating

in

making

modifications

to

the

prototype.

The

final

steps

are

to

test

those

modifications,

analyze

the

results

and

make

recommendations

based

on

the

analysis.