Design team members: Simon Drexler, Chris Jowett, and Andrew DiMaria

Supervisor: Professor M.J. Worswick

Background

A common problem for the one million registered hockey players across North America is finding a hockey stick with attributes that are suited to their personal preferences. Professional hockey players routinely have completely customized sticks made for them. This however is not a viable option for the average consumer who must choose a stick from those available at local sporting goods stores. Due to the limited stock of such stores and the vast number of combinations of various stick attributes, it can be near impossible to find a stick meeting all of a player's criteria. A need exists for players to be able to customize stick attributes themselves. This will enable players to match a stick to more of their desired characteristics and avoid the high cost of custom made sticks.

Project description

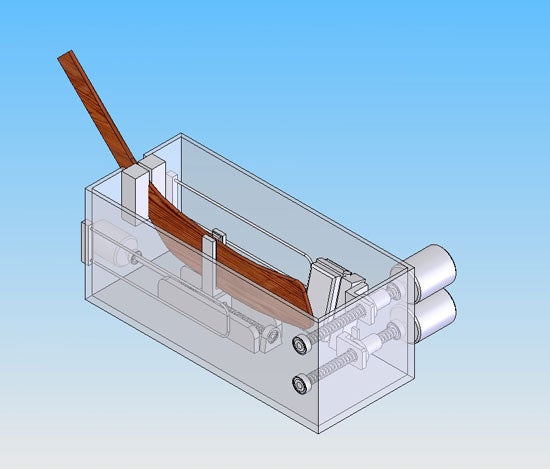

One attribute of a hockey stick that can easily be adjusted by the average consumer is the curvature of the blade. Current methods of doing so provide unrepeatable results and are subject to an uncontrolled heat application, generally done using a torch that can damage the blade. The problem we aim to address in this design project is the current lack of an inexpensive, highly repeatable, and low-error process for custom curving hockey stick blades. A unit will be designed to take user inputs which define the desired blade curve for their hockey stick, and using a series of automated mechanisms in a controlled environment, the unit will customize the user's blade.

Design methodology

The nature of the project calls for a very hands on approach to building the end product. Because the composition of hockey stick blades is highly variable, it is almost impossible to predict their behaviour with mathematical analysis. To accurately produce a model of a blade's behaviour after force application, we are combining results of a series of bending tests with a mathematical model of the blades. Testing apparatuses and prototypes are designed and built as required by our group members. We will also use the skills learned throughout our Systems Design Engineering coursework to design a user interface which accepts appropriate inputs from the user and provides appropriate feedback. Circuitry will also be designed and implemented to control the operation of the automated blade curving device.