As the event approached, we applied and had been accepted to the hackathon, but we found ourselves faced with a difficult question. What are we going to build?

Step 1: Decide what to hack

Step 2: Find the right place to work

We began working in the 3D print center, but by Saturday afternoon we had moved downstairs closer to the engineering student machine shop.

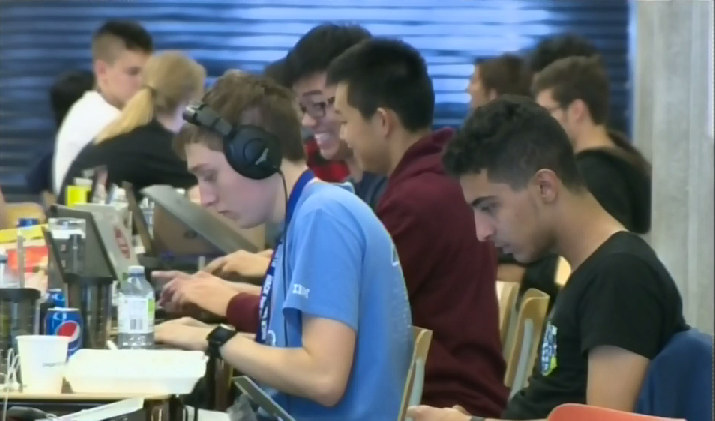

Coincidentally, CTV was filming a story about the hackathon nearby. Because we were so close to their crew, I was interviewed for a news piece that appeared on television that night. If we had stayed in the print center all weekend, we wouldn’t have had this opportunity. Moving into the busier areas of E5 was distracting at times, but also gave us access to the resources that we needed to finish our project, and extra exposure of our company.

Step 3: Make connections

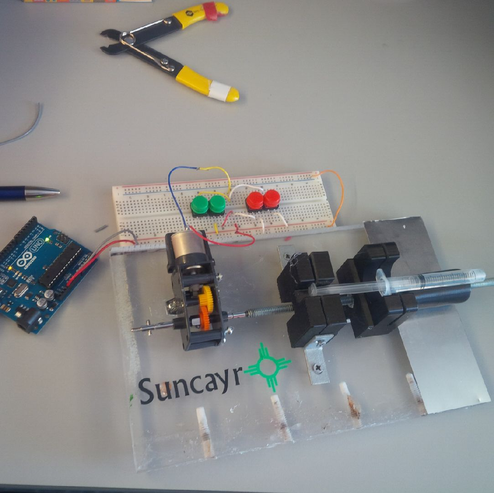

There is no way that we would have been able to finish our syringe pump if not for the connections we made both before and during the hackathon. The connection that proved to be the most useful to us was our strong relationship with the guys at Lani. Because of this, at 11:30 p.m. on Friday night when hacking began, we were first in line to get our items 3D printed. This put us in a great position to start building the next morning.

Step 4: Know your judges

We went into this hackathon knowing that we were building something completely different from most of the other teams, and that there would be limited prizes available for a hardware hack. When we went to present to the judges on Sunday afternoon, we really just wanted to show them the passion that we have for our company, and how much of an impact our syringe pump would have on our future tech development.

We were fortunate enough to have Ted Livingston as one of our judges. Ted is the CEO of Kik, and the person responsible for the creation of the Velocity Venture Fund (now the Velocity Fund Finals competition). Our product clicked with him right away, and although we didn’t win anything at Hack the North, we made a connection that could be extremely beneficial to our company in the long run.

Step 5: Have fun and build cool stuff!

About Rachel

BET 300 student, Rachel Pautler.

Rachel is a co-founder and the CEO of Suncayr. Rachel is currently in her fourth year of Nanotechnology Engineering at the University of Waterloo. She co-founded a nanotech student team during her second year of school, and has conducted diverse research in materials science and the biological applications of nano through her co-op terms.

About Suncayr