If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

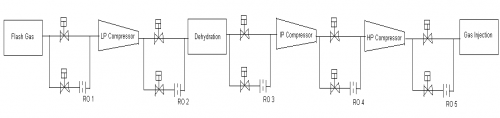

AKCS Offshore Partner, located in St. John’s Newfoundland, provides engineering, procurement and construction services to the offshore oil and gas industry in Newfoundland, Labrador and Atlantic Canada. A client of AKCS Offshore Partner was concerned with the time it took to pressurize the compressor trains in their offshore oil production facility. The compressor trains are used to re-inject gas into the well for storage. A portion of the same gas is flared to provide energy to operate the trains. Less time is desirable because it enables faster start-up and saves energy and thus money to run the compressor trains.

Laura Parsons, a chemical engineering student at the University of Waterloo worked with the Process Department at AKCS. She was asked to investigate this matter and determine the effect of altering the pressurization method and resizing of equipment on the time it takes to pressurize the compressor trains.

This case study is intended for use in chemical and/or mechanical engineering courses covering topics such as thermodynamics, mass transfer or process equipment.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.