If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

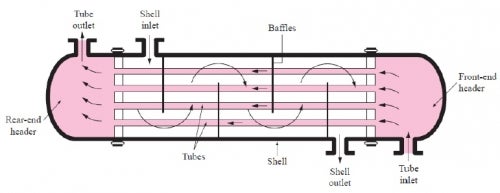

Babcock & Wilcox (B&W) Canada Ltd. is a subsidiary of Babcock & Wilcox Power Generation Group Inc., the largest steam generation product manufacturer and service provider in North America [1]. As the leading global supplier of thermal utility boilers, B&W engineers and manufacturers use a range of engineering tools, including commercial software packages, to analyze and advance company projects. The company recently explored the applicability of HTRI’s Exchanger Suite (Xist) software for B&W heat exchanger applications, directly comparing Xist simulation results against measured data and analytical models. Since Xist is capable of analyzing various types of heat exchangers, B&W had the option of choosing a single-pass, counter flow, shell-and-tube heat exchanger, hereafter referred to as ECW-HX1, Figure 1, for analysis.

Peter Plaisier, a 4th year Mechanical Engineering co-op student from the University of Waterloo, was asked to verify the accuracies of HTRI’s Xchanger Suite - Xist program simulation results against an analytical model and measured data [2].

Figure 1 - Main parts of single pass, counter flow, shell-and-tube heat exchanger

The primary teaching objective of this case includes the application of heat transfer equation for single pass shell-and-tube heat exchanger. The case can be used as an effective material for any course focusing on heat transfer.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.