If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

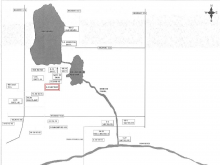

Cenovus Energy is an oil and gas producing company with operations throughout Alberta, British Columbia, and Saskatchewan. The company’s primary focus is exploration and operation of oil wells. The Oil & Natural Gas Business Unit in Brooks, Alberta supports operations of existing oil wells and an oil and gas processing plant. An oil and gas plant is located approximately 25 kilometers south of Brooks, Alberta, and is illustrated geographically using the Alberta Township system in Figure 1, outlined in red. Natural gas is entrained in the oil and is collected during oil processing. The gas contains hydrogen sulfide (H2S) and must be “sweetened” by removing the H2S; this requires an increase in gas pressure. The three current gas compressors were initially configured to handle large volumes of gas, significantly greater than the current production, although new wells have the potential to increase this gas volume. It was necessary to evaluate the existing gas compressors at the Cenovus oil and gas plant, based on collected data, maximum volume capacity and monetary operating costs, to recommend an optimal operating mode.

Cenovus Energy is an oil and gas producing company with operations throughout Alberta, British Columbia, and Saskatchewan. The company’s primary focus is exploration and operation of oil wells. The Oil & Natural Gas Business Unit in Brooks, Alberta supports operations of existing oil wells and an oil and gas processing plant. An oil and gas plant is located approximately 25 kilometers south of Brooks, Alberta, and is illustrated geographically using the Alberta Township system in Figure 1, outlined in red. Natural gas is entrained in the oil and is collected during oil processing. The gas contains hydrogen sulfide (H2S) and must be “sweetened” by removing the H2S; this requires an increase in gas pressure. The three current gas compressors were initially configured to handle large volumes of gas, significantly greater than the current production, although new wells have the potential to increase this gas volume. It was necessary to evaluate the existing gas compressors at the Cenovus oil and gas plant, based on collected data, maximum volume capacity and monetary operating costs, to recommend an optimal operating mode.

Dominic Toselli, a co-op student from the University of Waterloo, was asked to investigate the gas compressors at the Cenovus oil and gas plant to recommend the optimal compressor configuration for daily operation.

The teaching objective of this case is to use compressor operating principles and compressor curves to compare two reciprocating compressors in use at Cenovus and recommend a compressor for daily use based on capacity and monetary operating costs. The case study is intended to introduce concepts of compressor operation, oil and gas processing, and energy cost analysis. The case can potentially be used in MSCI 261 (Engineering Economics: Financial Management for Engineers), CHE 100 (Chemical Engineering Concepts 1), ME 100 (Mechanical Engineering Communication and Professionalism) and CHE 480 (Process Analysis and Design).

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.