If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

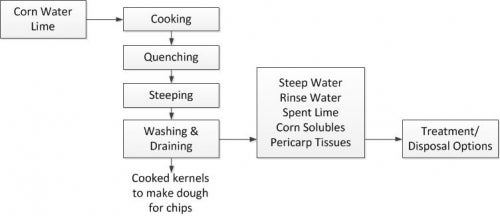

The corn chip manufacturing process, outlined below, involves two major stages: the preparation of dough (masa) from raw corn kernels and subsequent manufacture of tortilla chips from the prepared masa. Water is used in the masa preparation process for cooking, soaking and washing, producing a large volume of wastewater per unit of tortilla chips.. The wastewater stream, called nejayote, contains dissolved and suspended solids that incur high sewer surcharges. The potential benefits from removing components of the solid waste in-house, prior to sending the stream to the municipal wastewater treatment facility, are threefold: (i) reduced waste offers the potential to avoid expensive surcharges, (ii) should the collected solid components prove valuable, the company may develop an additional revenue stream, and (iii) reduced freshwater usage reduces environmental impacts.

Anna Shen, Adam Vogt, Winnie Huynh and Whitney Wong, a team of 4th year Chemical Engineering students at the University of Waterloo, were asked by a local company to propose waste-redirection alternatives for its tortilla chip manufacturing line as part of their 4th year design project, supervised by Professor Christine Moresoli [1].

The teaching objective of this case is to illustrate the design process and a variety of chemical engineering unit operations in practice.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.