If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

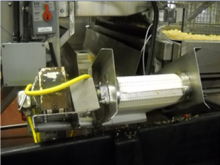

Frito-Lay, located in Cambridge, Ontario, is Canada’s largest snack food manufacturer, producing a range of brands such as Lays, Ruffles, Miss Vickie’s, Sun Chips, Doritos, Tostitos, Cheetos, and Smartfood. One of the machines in the potato chip production line detects and separates defective potato chips and places them on a conveyer line, separate from the main chip line. The defective chips are subsequently conveyed into a large waste bin, as partly shown in Figure 1. The waste bin is replaced when it is full; in order to reduce the frequency of this process manual crushing is done with a tamper tool. Manual crushing of potato chips is repetitive, time consuming, and involves a straining motion, with potential for ergonomic injuries and decreased production efficiency. A potato chip pulverizing unit has the potential to increase potato chip production efficiency, resulting in significant cost savings. There is a clear need for a potato chip pulverizing unit at Frito-Lay to ensure workplace safety and increase potato chip processing efficiency.

Frito-Lay, located in Cambridge, Ontario, is Canada’s largest snack food manufacturer, producing a range of brands such as Lays, Ruffles, Miss Vickie’s, Sun Chips, Doritos, Tostitos, Cheetos, and Smartfood. One of the machines in the potato chip production line detects and separates defective potato chips and places them on a conveyer line, separate from the main chip line. The defective chips are subsequently conveyed into a large waste bin, as partly shown in Figure 1. The waste bin is replaced when it is full; in order to reduce the frequency of this process manual crushing is done with a tamper tool. Manual crushing of potato chips is repetitive, time consuming, and involves a straining motion, with potential for ergonomic injuries and decreased production efficiency. A potato chip pulverizing unit has the potential to increase potato chip production efficiency, resulting in significant cost savings. There is a clear need for a potato chip pulverizing unit at Frito-Lay to ensure workplace safety and increase potato chip processing efficiency.

Jeffrey Azzolin, a University of Waterloo co-op student working for the engineering department at Frito-Lay, was assigned to design, fabricate, test, and install a potato chip pulverizing unit.

The teaching objective of this case is to illustrate the engineering design process. The main expected learning outcome is for students to practice design synthesis. It is intended that the case study be open-ended, where students will need to move through the engineering design process, and conceptualize adequate solutions based on the design requirements. The case is applicable for ME 100 (Mechanical Engineering Communication and Professionalism), SYDE 161 (Introduction to Design), ME 321 (Kinematics and Dynamics of Machines), ME 380 (Mechanical Engineering Design Workshop), and SYDE 361 (Engineering Design).

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.