If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

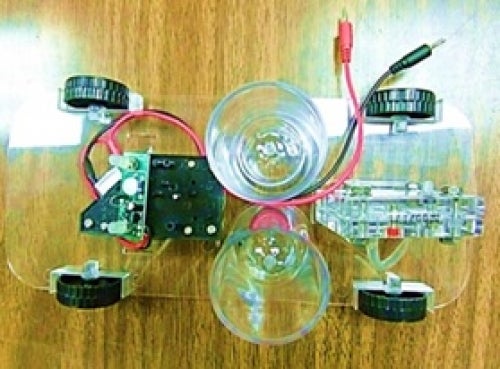

A fuel cell car project was introduced in the Mechatronics Engineering program at the University of Waterloo in 2012 to increase student hands-on learning in first year courses. The students were asked to assemble the cars themselves from a commercial kit, Figure 1, and then complete labs on hydrogen fuel cells, electrical circuits and programming, with the ultimate goal of having the vehicle autonomously follow a test track. Although the project was generally successful in integrating learning between three different courses, there was a desire to improve these model cars. They had limited maneuverability, were not easily controllable by the students and did not run for sufficient periods of time using the hydrogen fuel cells. This caused frustration among the students who felt they did not have adequate control over their success in the project. A redesign of the vehicles was required. Additional sensors and a programmable microcontroller were desired to increase controllability. These new requirements necessitated a re-design of the chassis in order to properly manage static and dynamic loads, increase durability, improve handling and effectively package all components of the vehicle.

Geoffrey Iwasa, a third year mechanical engineering student from the University of Waterloo, was asked to assist in the redesign of the chassis as well as analyze successful aspects of the new chassis and determine if there are further improvements for reliability, performance and quality of learning.

Figure 1 - Top view of model fuel cell vehicle, original chassis design

This case is intended for students to apply their knowledge of fuel cell cars and mechanical design to a specific design opportunity. They will need to first understand the design requirements and then analyze each part individually and as part of an assembly in order to come up with a design for this case study that is fully reliable and effective.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.