If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

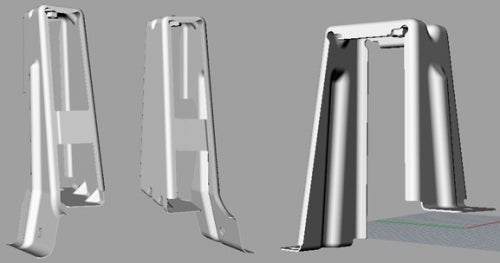

Nahanni Steel Products (Nahanni), located in Brampton, Ontario, is a Tier 2 supplier that provides products and services to the automotive, mining and solar industries, as well as to both residential and commercial roofing businesses. Nahanni’s specialty, however, is automotive parts manufacturing. They offer a range of fabrication processes, including stamping, welding, assembly, press tool and injection mould builds. In the summer of 2014, Nahanni was awarded a contract to produce three automotive brackets, Figure 1, which serve as a cargo floor support to hold up a plastic floor in the back of a vehicle. The production of these steel brackets requires the use of 2 automated welding machines and a press, with production volumes of at least 80,000 parts per year. To proceed with production, Nahanni Steel Products requires a process flow and schedule that will efficiently produce all three parts.

Darrin Wiegard, a plant engineer at Nahanni Steel Products, was responsible for determining the most efficient work process to produce these automotive brackets.

Figure 1 - Diagram of the three automotive brackets planned for production

Figure 1 - Diagram of the three automotive brackets planned for production

The teaching objective of this case is to give students the opportunity to practice work place design and facilities planning. The case exposes students to basic concepts such as process analysis, flow design, facility location, and layout.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.