If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

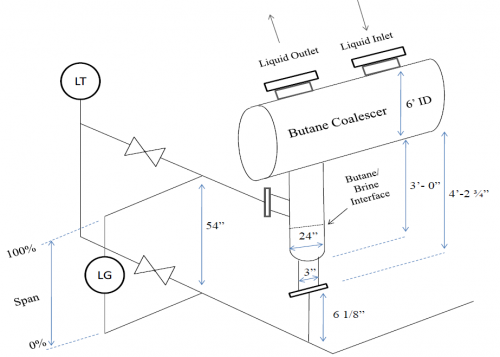

NOVA Chemicals, located in Sarnia, ON, produces plastics and chemicals essential for everyday life. The company manufactures materials for customers worldwide who produce consumer, industrial and packaging products. Butane is a hydrocarbon which is stored in an underground salt cavern at the facility. Due to the interfacial interaction of butane gas with brine within the cavern, a small quantity of brine becomes dissolved in the gas. In order to remove the dissolved brine from butane, a coalescer vessel is used as illustrated in Figure 1. In 2010, the dry flare vaporizer, a piece of equipment downstream of the butane coalescer, failed due to chloride induced stress or corrosion because of the brine which may have been present in the vessel. Damage to process equipment such as the vaporizer severely affects functionality, leading to high replacement costs and production downtime. While investigating the failure of the dry flare vaporizer, it was suspected that abnormal operating behavior of the butane coalescer upstream of the equipment had been the cause of the failure.

Anyssa Mohammed, a University of Waterloo co-op student, was part of the process design team at NOVA Chemicals assigned to determine the cause of the irregular behaviour of the butane coalescer.

The teaching objective of this case is to illustrate chemical engineering concepts including process trend analysis, liquid-liquid separation, solubility, and interfacial interactions. The main expected learning outcome is for students to determine the cause of the irregular butane coalescer behaviour and propose a solution to improve operations. The case is applicable for CHE 200 (Equilibrium Stage Operations), CHE 330 (Chemical Engineering Thermodynamics), CHE 230 (Physical Chemistry 1), CHE 231(Physical Chemistry 2), and CHE 480 (Process Analysis and Design).

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.