If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

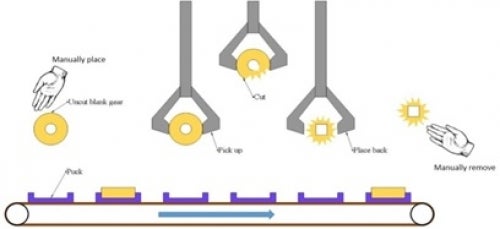

Ontario Drive & Gear (ODG) is a Canadian manufacturing company specializing in manufacturing high precision gears and couplings as well as assembly of various low volume transmission components. ODG uses manufacturing automation methods for many mid quantity gear cutting operations to increase production efficiency. To do this, automation pucks are used to transport gears in and out of machines which is depicted in Figure 1. The puck is a specially-shaped plastic tray that fits onto the gear cutting machine’s conveyor belt and it provides a stable fixture on which the gear rests. The current pucks are machine and part-specific and must be changed for each different part that is manufactured. This means that new pucks must be made for each different size of gear product and all the pucks on the conveyor belt must be replaced. This process is very time consuming and costly. The company is looking for a new automation puck system that can cut down on cost and retooling time.

This case study is intended to teach students application of engineering design concepts with a real-life engineering problem. The primary teaching objective of this case study is to illustrate the engineering design process to form a conceptual design based on the given information.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.