If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

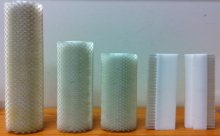

A pharmaceutical company packages solid-dose pharmaceuticals into various capacity bottles and blister pack formats. Several types of brushes are used in the blister pack production process. These brushes are used as part of the feeding system to insert tablets and capsules into the blister pockets. Upon completion of an order, product-specific brush kits are removed from the process equipment and cleaned according to regulatory requirements. The drying time for the brushes is significant, between two to four hours in a gravity convection dryer. Based on an examination of solid-dose production runs over a six month period, an average 41% of the total downtime consisted of setting up equipment for a production run or cleaning equipment from a previous production run. An alternative solution was desired to reduce downtime for cleaning, and for energy savings.

A pharmaceutical company packages solid-dose pharmaceuticals into various capacity bottles and blister pack formats. Several types of brushes are used in the blister pack production process. These brushes are used as part of the feeding system to insert tablets and capsules into the blister pockets. Upon completion of an order, product-specific brush kits are removed from the process equipment and cleaned according to regulatory requirements. The drying time for the brushes is significant, between two to four hours in a gravity convection dryer. Based on an examination of solid-dose production runs over a six month period, an average 41% of the total downtime consisted of setting up equipment for a production run or cleaning equipment from a previous production run. An alternative solution was desired to reduce downtime for cleaning, and for energy savings.

Pavan Mehta, a second year Chemical Engineering co-op student at the University of Waterloo, looked at the effectiveness of a brush spinner and corresponding jig design to hold flat brushes for drying at the pharmaceutical packaging facility.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.