If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

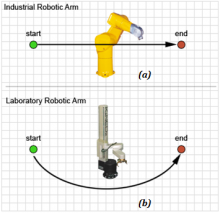

ReTiSoft is a software research and development enterprise based in Mississauga, Canada. The company is a provider of turnkey and custom automated systems for the pharmaceutical, biotechnology, and research industries. ReTiSoft software is used to control and schedule the movements of a robotic arm as it transports microplates and vials between pre-programmed stations (nests), in order to automate laboratory experiments. A problem arose when attempting to integrate an industrial robotic arm, namely the Stäubli TX-40, as opposed to the typical laboratory arms with which ReTiSoft previously dealt. The Stäubli TX-40 robotic arm functions differently from the regular robotic arms designed for moving resources in a laboratory environment as shown in Figure 1. The industrial robotic arm had no firmware of its own and the programming environment supplied with the arm was very limited.

ReTiSoft is a software research and development enterprise based in Mississauga, Canada. The company is a provider of turnkey and custom automated systems for the pharmaceutical, biotechnology, and research industries. ReTiSoft software is used to control and schedule the movements of a robotic arm as it transports microplates and vials between pre-programmed stations (nests), in order to automate laboratory experiments. A problem arose when attempting to integrate an industrial robotic arm, namely the Stäubli TX-40, as opposed to the typical laboratory arms with which ReTiSoft previously dealt. The Stäubli TX-40 robotic arm functions differently from the regular robotic arms designed for moving resources in a laboratory environment as shown in Figure 1. The industrial robotic arm had no firmware of its own and the programming environment supplied with the arm was very limited.

Maciej Makowski, a co-op student from the University of Waterloo, was asked to develop a device driver for this new industrial robotic arm.

The learning objective for this case study including needs analysis, device level and frame work control system design, developing the design criteria and constraints for this particular software requirements problem.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.