If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

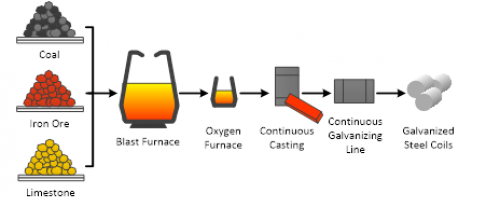

Steel is an essential component of the modern world. Galvanized steel products are strong and corrosion resistant and used for a wide range of applications in such places as the automobile, appliance, and construction industries. The steel manufacturing process, as illustrated in Figure 1, consumes a large amount of energy for steel production. Decreasing the plant energy consumption is a method to decrease overall plant operating costs. A Continuous Galvanizing Line produces galvanized steel using the hot-dip method. Hot-dip galvanizing coats the steel by passing the metal through a molten bath of zinc at a temperature of 460°C. After galvanization the steel is coiled for storage and customer delivery. The system used for heating the coiling area of the line is a forced-air system. Four heating systems were considered for heating the coil manufacturing area and investigated for potential energy cost savings. The four systems are: forced air, torpedo natural gas heaters, radiant tube heating, and radiant panel heating. The objective is to find the system with the lowest energy requirement that is safe and capable of producing the necessary amount of heat for the space.

The teaching objective of this case is to complete a needs analysis for a heating system used in a steel production warehouse and to perform background research on galvanized steel production. The case study is intended for use in CHE 100 (Chemical Engineering Concepts 1) as a conceptual design case.

If you would like to see more information on this case study, click here!

You can request this case study and a WCDE staff member will get back to you.

Contact Waterloo Cases in Design Engineering

Steve Lambert

Tel: (519) 888-4728

Email: steve@uwaterloo.ca

The University of Waterloo acknowledges that much of our work takes place on the traditional territory of the Neutral, Anishinaabeg, and Haudenosaunee peoples. Our main campus is situated on the Haldimand Tract, the land granted to the Six Nations that includes six miles on each side of the Grand River. Our active work toward reconciliation takes place across our campuses through research, learning, teaching, and community building, and is co-ordinated within the Office of Indigenous Relations.