Professor Tizazu Mekonnen’s research group have designed a novel material that absorbs oil from spills and also prevents any groundwater leeching, making it an ideal material to treat future pollutant contamination and spills.

The porous material designed from special tri-block co-polymers can absorb eight times its weight or 800% of oil upon direct contact.

Oil spills pose serious environmental, social and economic impacts. These spills are a common environmental hazard in marine environments but also occur on land leeching into groundwater. Groundwater contamination is extremely difficult to clean up and can lead to health problems for both wildlife and people.

Electric transformers and other industries often operate oil storage facilities that could leak into groundwater due to unexpected accidents or natural disasters such as tornadoes, earthquakes, and hurricanes.

“The current technology for oil capture is lagging,” says Mekonnen, a Canada Research Chair in Sustainable Multiphase Polymers. “Preserving our environment is crucial, which is why developing these advanced technologies, like this polymer is essential for remediating future groundwater contaminants like oil.”

Industry Partnership

Mekonnen’s research team, in collaboration with Albarrie Canada and the Ontario Centre of Innovation (OCI), has developed a porous material that will act as a barrier under oil storage facilities.

Currently, liners are used under electrical transformers to prevent oil from leaking into the ground. The problem with existing liners is they will leak if the material reaches its saturation point. They behave like a sponge, which can only absorb a finite amount of oil spill. Once saturated, oil will ooze through the lining into the groundwater.

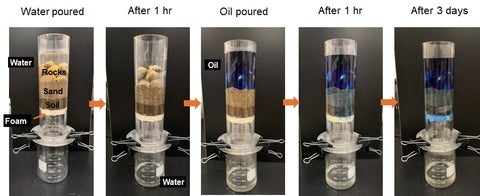

Unlike traditional liners that leak when saturated, this new polymer foam Mekonnen’s group designed turns into a gel upon contact with oil, sealing it in and preventing groundwater contamination.

The chemical structure of the polymer material is unique. Its lightweight foam structure resembles a yoga mat’s spongy texture, but it becomes a gel-like substance once it comes into contact with oil, providing a complete barrier for possible oil leaks.

Environmental Remediation

This technology can also be used to remediate ocean oil spills. While there are materials currently used to absorb oil from oceans, the oil may leak out once the absorbent material is extracted from the water. This new material developed by Mekonnen, and his research team traps oil with no chance of it oozing out. It’s also lightweight and easy to transport and the oil itself can also be completely recovered in a secondary process.

“This innovation has the potential to safeguard both marine and terrestrial ecosystems, ensuring a healthier environment for wildlife and humans alike," says Mekonnen. "The impact of this polymer extends beyond immediate spill response, offering a sustainable solution for long-term environmental remediation."

The next step in Mekonnen’s research is to scale up from lab to real-world applications. Mekonnen’s research group is committed to continuing to support scale-up and practical application activities.

The study, “Fabrication of Triblock Elastomer Foams and Gelation Studies for Oil Spill Remediation, was recently published in Macro Molecular Rapid Communications.

The three images on the right show the water can pass through the foam and oil is trapped