Design team members: Roanne Sones and Allan Colquhoun

Supervisor: Prof. Erik Kubica

Background

Volleyball is an appealing and challenging game. Although growing in popularity and improving in quality, it is very difficult to refine your skills without many players participating. For many elite athletes and teams, this is a concern.

Blocking in volleyball involves between one and three players of the opposing team jumping in unison to create a wall above the net with their hands. Ideally this wall will block the ball down to the court on the attackers side. An effective block is often the difference in a game, and successfully avoiding the block is a skill all players seek to improve.

Creating a mechanical blocking system for our fourth year project will allow players to develop the essential skill of spiking the ball around the block, without requiring the presence of other elite players to form the block. In team practice situations, players won’t be required to perform the blocking, allowing all players to practice their spiking skills at the same time, if so desired.

Having both spent significant amounts of time playing varsity volleyball, the problems noted above have been very apparent and often frustrating for us on a personal level. Given the chance to combine two activities (engineering and volleyball) to which we have dedicated so much of our time over the last five years and provide an improved training environment provided the motivation for this project.

The first step in this project is to determine the requirements to build a volleyball blocking system prototype that will improve the training for an advanced volleyball player. Having established these requirements, designs will be considered that will attempt to address them. The various potential designs will be evaluated against the requirements and a final design will be selected. The final stage of this project will be to completely design the selected design and attempt to build a fully functional prototype.

Project description

At this point in time, we are working on fully designing our selected, final prototype design. The following describes some of the major components of the system, the alternatives considered for each, and a description of the final design.

One of the first steps we took to begin considering possible designs was to establish major components of the system. The major components consisted of: the blocking surface, the control system, the mechanical system and the anchoring system.

Blocking

Surface

The

blocking

surface

is

the

component

of

the

system

that

will

be

above

the

net

and

will

‘block’

the

ball

attacked

by

the

spiker.

It

was

important

to

develop

a

blocking

surface

that

reflects

the

ball

realistically,

that

won’t

be

broken,

and

was

light

enough

to

dynamically

move.

Eliminating

heavy

materials

such

as

wood

and

metal,

we

were

left

with

lexan

and

acrylic.

Performing

stress

analysis

and

investigating

the

reflection

properties

of

lexan

and

acrylic,

it

was

determined

that

the

blocking

surface

would

be

made

of

lexan.

Control

System

The

control

system

provides

the

system

the

intelligence

it

needs

to

accomplish

the

dynamic

aspects

of

its

requirements.

Responding

to

inputs

and

triggering

outputs

were

to

be

handled

by

a

PC,

a

micro

controller,

a

PLC

or

simply

a

series

of

switches.

At

this

point,

a

final

control

system

hasn’t

been

selected.

However,

a

PC

is

unlikely

due

to

cost

and

difficulty

of

I/O,

and

a

series

of

switches

is

unlikely

due

to

the

limited

control

offered.

Mechanical

system

The

portion

of

the

system

involved

in

moving

was

dubbed

the

mechanical

system.

There

were

two

main

options

that

were

considered

for

the

mechanical

system.

The

first

consisted

of

pneumatic

cylinders

being

attached

to

the

blocking

surface.

When

the

compressed

air

source

provided

pressurized

air

to

the

cylinder,

the

blocking

surface

would

be

raised

into

blocking

position.

There

could

be

up

to

three

cylinders,

each

controlling

one

blocking

surface.

The

other

option

was

to

use

a

pulley

system

using

motors.

Stepper

motors,

AC,

DC

and

Universal

motors

are

all

options

for

a

motor-based

solution.

Due

to

cost,

pneumatic

cylinders

have

been

eliminated.

The

type

of

motor

has

not

yet

been

established,

as

cost/benefit

analysis

for

the

various

types

is

ongoing.

Anchoring

System

The

final

major

component

was

the

anchoring

system.

This

provided

the

means

by

which

the

system

would

remain

stationary

during

the

impact

of

the

spike.

Two

approaches

were

considered,

attaching

the

anchoring

system

to

the

pole

system,

and

having

a

freestanding

anchoring

system.

Market

research

revealed

that

one

type

of

pole

dominated

the

market,

with

one

other

type

having

some

market

share.

However,

the

ease

installation

and

removal,

the

flexibility

and

the

safety

concerns

led

us

to

select

a

freestanding

anchoring

system.

Selected design

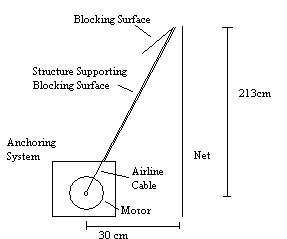

Although we arrived at our final design through the methodology described below, the discussion of the major system components provides good insight into the final, selected design. The final design is a motor-based design that will be anchored via a freestanding base. This base will house both the motors and the control system, when selected. The blocking surface will be raised into place by a pulley system and the structure will be clipped to the net at the top of the net to ensure the system will be able to withstand the force of a volleyball spike. A simple diagram of the system can be seen below in Figure 1.

Design Methodology

After numerous brainstorming sessions, the group finally settled on seven distinct prototype designs. The immediate goal at this stage of the design process was to determine what prototype should be selected for development.

In order to select only one prototype for development, we needed to come up with a set of criteria to evaluate the prototypes. The criteria selected were representative of high-level design requirements and were used to easily differentiate between the different prototypes. Table 1 details the selection criteria and the average metric in the unit of measurement of the criteria as determined by the group.

| Selection Criteria | Average Metric |

|---|---|

| Cost | Less then $300 |

| Ease of manufacture | Can be completed in 4 months |

| Ability to reflect the volleyball | Will accurately reflect the volleyball |

| Ability to simulate double block | Can create a single, double, cross and line block |

| Power requirements of system | Will require only an AC source to run |

| Ease of replacement components | Cost and location of replacement products |

| Portability | Can be carried by one person |

Table 1: Selection and average metric used as reference for different prototypes

With our selection criteria determined we then chose to set up a concept-screening matrix. Each prototype was deemed above average, average or below average for selection criteria in Table 1. This ultimately eliminated two prototypes that were below average on almost all aspects of the selection criteria.

The field was now narrowed down to only five prototypes. To select the final prototype for development a concept-scoring matrix was created. This primary purpose of this matrix was to take the priority levels of the selection criteria into account. The different priority levels were given associated weights that were used to consider the overall ranking of each prototype. Due to the nature of the project, the group decided to place a weight of 25% to both cost and ease of manufacture. As the project is only 8 months in duration, and we are still paying tuition, these are the limiting factors to our success.

Although a fairly close result, in the end Prototype 7 proved to most favourably meet the selection criteria.