Shadab is passionate about projects that aim to improve environmental sustainability and make a positive impact on people's lives. She has noticed that in recent years, there has been a growing focus on the environmental impact of transportation, especially in its role in global warming. Because of this, she is researching advanced welding and joining techniques and utilizing lightweight materials in automotive components to help reduce greenhouse gas emissions while enhancing the safety aspects of vehicles.

Shadab says the following drew here to her PhD program in the Department of Mechanical and Mechatronics Engineering at the University of Waterloo:

"The Faculty of Engineering at the University of Waterloo provides the perfect environment for learning, advanced research, and a supportive community that fosters innovation. On ranking websites, the University of Waterloo's Faculty of Engineering, particularly the Department of Mechanical and Mechatronics, is ranked among the most renowned engineering departments in the world. I chose here to pursue my studies for a few reasons:

1. Cutting-Edge Research: Researchers in the faculty are at the forefront of advances in technology and engineering practices in their fields of expertise.

2. Industry Connections: The Faculty of Engineering has strong ties to industry leaders, offering students the opportunity to connect with them and gain insight into the field.

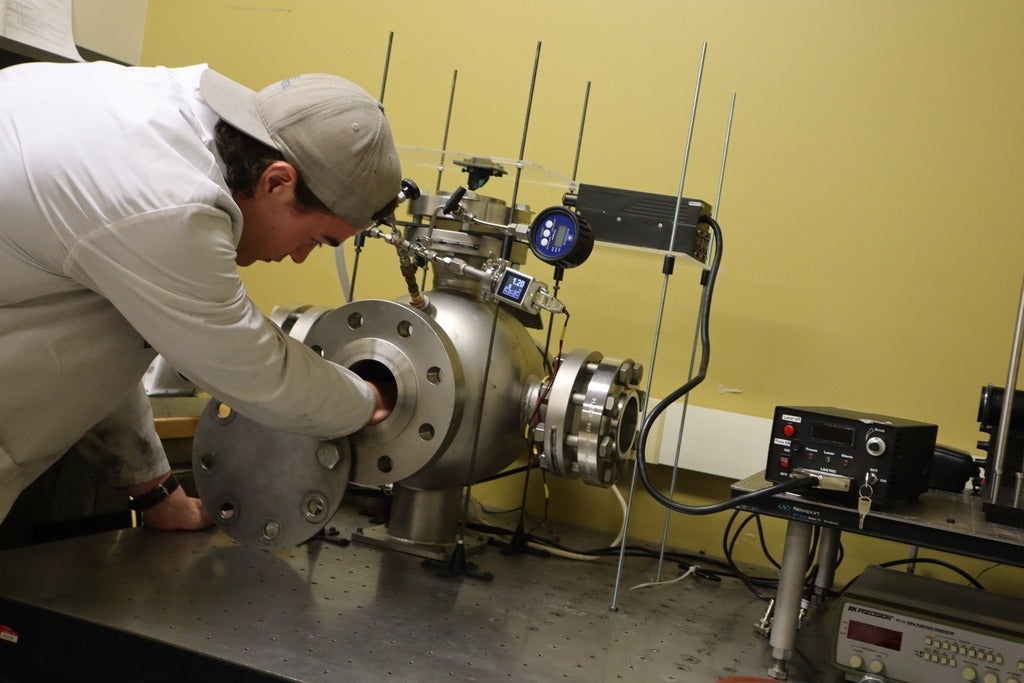

3. Modern Facilities: The facilities at the departments support hands-on learning and experimentation through well-equipped laboratories and advanced equipment.

4. Diverse Programs: Students can choose from a wide range of engineering programs to suit their interests and career goals."