Research in Mechanical and Mechatronics Engineering at the University of Waterloo

Light Weight Materials for Automotive Research

In Michael Worswick’s automotive research lab, metal and other materials are put to the test, to measure how much stress, tension, pressure and strain they can take. A Canada Research Chair and a Professor in the Department of Mechanical and Mechatronics Engineering, Dr. Worswick leads a research team that punishes metal and other materials en route to a lighter, safer automobile. (Read More)

Design of Virtual Crash Test Dummies

Dr. Duane Cronin is building a better crash test dummy — one that’s a little more forthcoming than its predecessors. Dr. Cronin aims to create a human body model, one that is both biofidelic — a faithful reproduction of the real thing — and frangible — so that it fails in the same way as a real human body would. It’s a project that brings together an understanding of the geometry of a car crash, of the mechanical properties of human tissue and how it deforms on impact, and the computing power to calculate all the many variables (Read More).

Intelligent Road Vehicles

Dr. Amir Khajepour’s automotive research focuses on improving vehicles by introducing intelligence that goes into cars, highways, signs, and the electricity grid. Dr. Khajepour, a Tier-1 Canada Research Chair and 25 other researchers bring a wide range of expertise to Green Intelligent Transportation Systems, a $24-million project based at the University of Waterloo. Through mechatronics, mechanical, electrical, information technology, chemical, transportation, and other disciplines and industry partnerships, they see a cleaner, smarter future for driving. (Read More)

MEMS Sensors for Biomedical Research

Dr. Patricia Nieva, a professor in mechanical and mechatronics engineering, is leading an international multidisciplinary team to build a BioMEMS monitor for early prediction of heart attacks. She already has a hospital lined up for the clinical testing and a company interested in commercializing the technology within five years. (Read More)

Lab-on-chip Research

Today’s labs-on-a-chip devices are made of polymers and plastics in addition to silicon materials and contain multiple channels able to conduct separate tests at the same time. Waterloo mechanical and mechatronics associate professor Carolyn Ren has devised a revolutionary way to both control the flow of liquids through the chip, and to monitor and heat the fluid as required. (Read More)

Fuel cell research

Dr. X. Li and his research group here at the University of Waterloo are currently focused on promoting green (or greener) energy through energy diversification and energy localization for sustainable development and energy security. One of Dr. Li's endeavors in green energy research focuses on Energy Conversion Technologies such as polymer electrolyte membrane (PEM) Fuel Cells, Direct Methanol Fuel Cells, solid oxide fuel cells: energy and exergy analysis, transport phenomena modeling and cell performance.

Wind tunnel research

The presence of solid boundaries in wind tunnels is known to give rise to detrimental aerodynamic blockage effects. Our 2'x3' adaptive-wall wind tunnel offers a unique solution to this problem. In particular, blockage effects can be virtually eliminated by configuring the wind tunnel walls to imitate the shape of outer streamlines in an unbounded flow field. The free-stream velocity in the wind tunnel can be adjusted from 2.5 m/s to 50m/s, making it suitable for studying various fluid mechanics and aerodynamics problems.

Biodegradable materials and bone implants research

Dr. E. Toyserkani and Dr. Kaan Erkorkmaz are researching means to find simple, practical and inexpensive solutions to fabricate complex bone implants composed of Calcium Polyphosphate (CPP), which is a biodegradable material. Several programs featuring multiple parallel research thrusts including Selective Laser Sintering, Binder-based Rapid Prototyping, Indirect rapid prototyping and CNC Surface Machining of CPP blocks are being pursued to arrive at the proposed objective.

Cable-based robots research

Based on the advantages of parallel and cable based manipulators, a new class of cable-based robots from 2 to 6 degrees of freedom has been developed and patented that can be used in ultra high-speed pick and place applications. In this new class of robots, cables are used not only to actuate the robot but to impose constraints on the motion of the end effector. For more information contact Dr. Amir Khajepour at 519-888-4567 x36159.

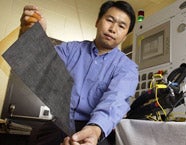

Turning a new artificial leaf

Professor Wu, joining University of Waterloo in 2019, led a collaborative effort discovering the "artificial leaf" process, converting CO2 and water to methanol using cuprous oxide. This innovation, bridging the lab to industry gap, attracted global scientific and industrial interest, but faced delays due to COVID-19 diverting crucial funding and resources. Nonetheless, Wu emphasizes its critical role against climate change, assisting large emitters in reducing emissions. The technology also promises a sustainable solution for electricity storage and distribution challenges in Canada, with the potential to significantly impact the energy sector. Wu continues seeking support to scale and commercialize this technology, initially in Canada before a global introduction.

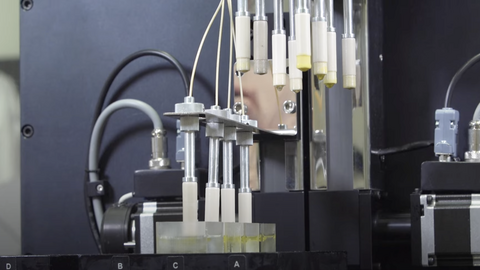

Low-cost method for encapsulation

Researchers at the University of Waterloo, led by Dr. Sushanta Mitra, have unveiled a cost-effective liquid-liquid encapsulation system, promising to revolutionize multiple industries. This method accurately encases core materials, using a nozzle to introduce a drop of the material into a host bath with a floating shell layer, creating a stable encapsulation. This innovative approach, with each encapsulation taking only 50 milliseconds, is 5000 times less energy intensive, eradicating microplastics from the process. The technology is adaptable, with 15 core-shell combinations demonstrated, and is especially promising for the nutraceutical sector by potentially reducing operational costs and spurring the development of new products. With a robust prototype capable of delivering 200,000 encapsulated cargos per hour, Mitra's team is collaborating with Dutch entities to further refine the technology, aligning with the UN's sustainable development goals.