In the view of Group CEO Alexis Nasard, innovation needs to become Bata’s number one competitive advantage. With this in mind, the Bata Innovation Lab (BIL) recently entered into a formal agreement with the Faculty of Engineering at the University of Waterloo in Canada, becoming the first global corporation to partner with the university and its world-renowned cooperative education (co-op) program, iCapstone. Offering students real-world work experience, the program provides Bata with fresh perspectives and the opportunity to analyze manufacturing processes from an engineering viewpoint.

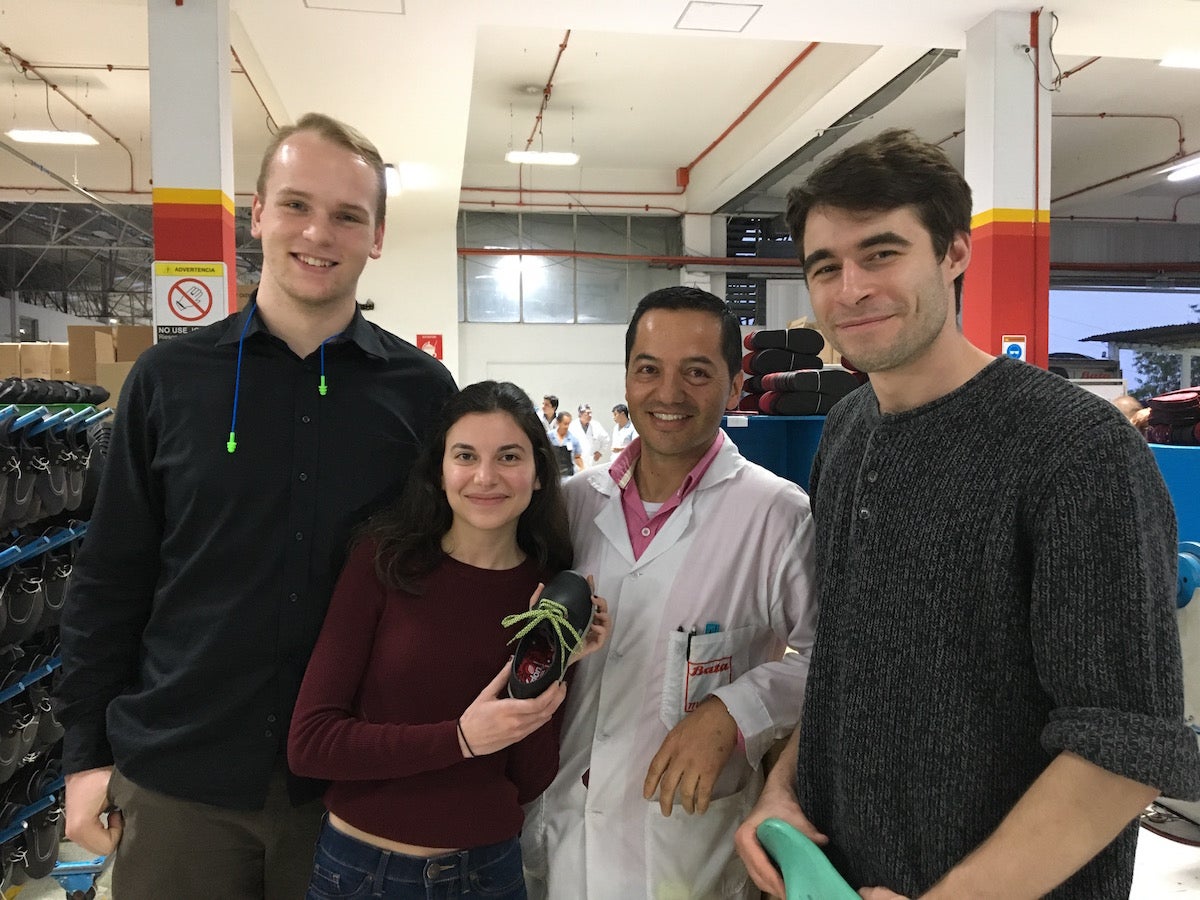

Sent to Bata’s factory in Manizales, Colombia for a four-month work term, Waterloo engineering students Pia Medina, Thomas Willert, and Jordan Nickel acted as external consultants, analyzing and improving on-site processes, efficiencies, and productivity.

When the students first arrived in Manizales in May 2017, no one knew for sure if or how the project would work. As it turned out, the students’ impact was soon felt. Claudio Alessi, country manager for Bata Colombia, explained: "We were very impressed with the students’ input, and immediately began implementing the projects and recommendations they presented to us."

Amongst the projects and recommendations was the development of a single shoe-rack system to improve the efficiency of targeted tasks on the conveyor. Testing and implementation are still being completed by Bata Colombia and, if successful, the system will be rolled out in Colombia and in other Bata factories following the same process.

Other recommendations implemented in the Manizales factory include:

- The installation of four sensors at different points on the line to control the time spent on task development

- The purchase of a new toe-lasting machine, which reduced wasted time, optimized shoe quality,

- minimized damage to shoe leather and improved productivity by 10 percent per shift

- The implementation of a motor tool for the second roughing of lasted shoes, which has maximized

- adhesion and decreased maladjustments by 70 percent

- The use of UV powder for sole tracing, which has improved quality and reduced time spent in the removal

- of excess glue on the shoe

The students also recommended the factory undertake research of delivery mechanisms for water-based resins.

The pilot project with Waterloo was a resounding success, as the students gained a deeper understanding of engineering design and practical on-the-ground experience to prepare them to enter the workforce as creative problem-solvers. For Bata, the project brought positive changes to the Manizales factory and Bata Colombia’s bottom line.

In the words of Oscar Nespoli, the lead Waterloo faculty member for the project and a Bata alumnus: "The project was a world-class learning experience for the students. Given the freedom to identify areas of improvement for the factory and to come up with meaningful strategies to address these issues, students acquired complex problem-solving skills. They reported that everything they learned ‘stuck so much better’ because they learned it on the job. We are all very grateful to Jim Russell and the Bata Innovation Lab for their vision and support of this valuable project."

From an innovation standpoint, it is evident that, by seeking input from outside partners and by looking critically at itself, Bata can make positive and measurable changes. Jim Russell, BIL director, stated: "I am exceptionally proud to have been a part of this successful pilot project. By immersing some of the brightest and most talented undergraduate engineering students from Canada’s University of Waterloo in the culture of the Bata Manizales factory and its best teams, BIL created an experience that was both unique and beneficial for everyone concerned."

The research that was undertaken as part of this new program will be presented at an international design conference in May this year in Dubrovnik, Croatia.