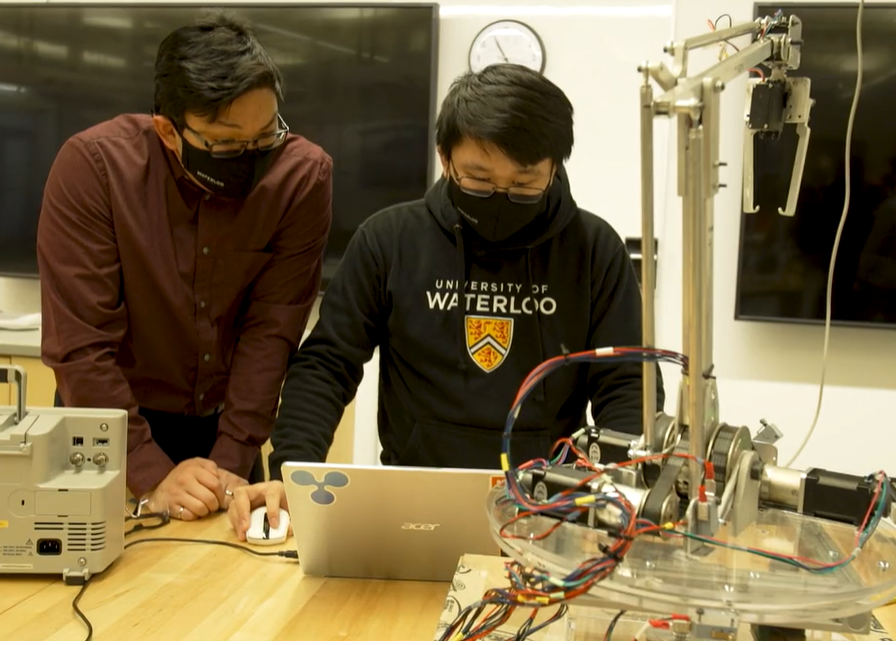

Waterloo Engineering has partnered with Inductive Automation, Brock Solutions and Opto 22 to create a small-scale automation project for students to gain hands-on knowledge of real-world equipment and tools.

Working in the Brock Solutions Industrial Hub, part of the Faculty's Engineering IDEAs Clinic™, students move small packages along four conveyor

The conveyor system, which includes programmable logic controllers (PLCs), belts, pulleys, bearings, gearboxes, motors, wiring, a camera, a diverter and software, helps students learn about automation, motion control, data management, factory planning, coding and more.

Over 400 students have participated in the industrial small-scale automation project.

“This project has provided me with some amazing design challenges, which I have really enjoyed working with and learning from,” said Rapti Ghosh, a third-year mechanical engineering student who spent a co-op term working at the IDEAs Clinic. “It has really pushed me to the next level in terms of my engineering skills and capabilities.”

The students' project work in the Engineering IDEAs Clinic™ is featured in a case study video by Inductive Automation.