The Faculty of Engineering hosted an innovation challenge funded by Toyota Motor Manufacturing Canada Inc. (TMMC) for engineering students in any program and in any year of study.

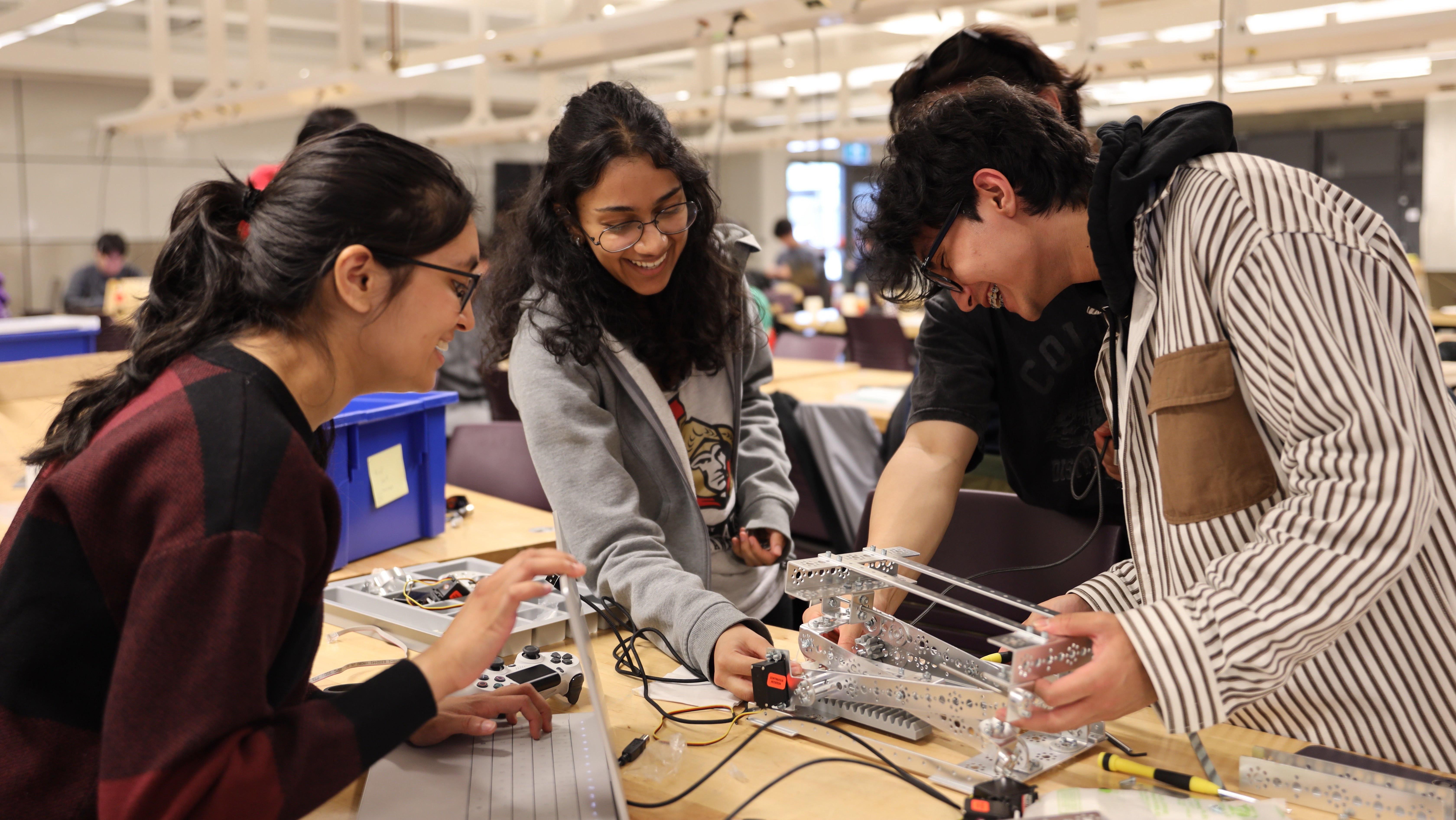

The weekend-long event, which took place in the Pearl Sullivan Engineering Ideas Clinic, challenged 125 students to design and prototype a robotic device capable of handling real-world automotive manufacturing tasks.

Engineers from TMMC introduced the challenge, drawing on their everyday work experiences and the issues they face. The students represented a cross-section of engineering programs—mechanical and mechatronics, software, management science, systems design, civil and environmental and nanotechnology—as well as computer science. In no time at all, they formed teams and got to work, tackling the problem of how to improve factory floor operations head on.

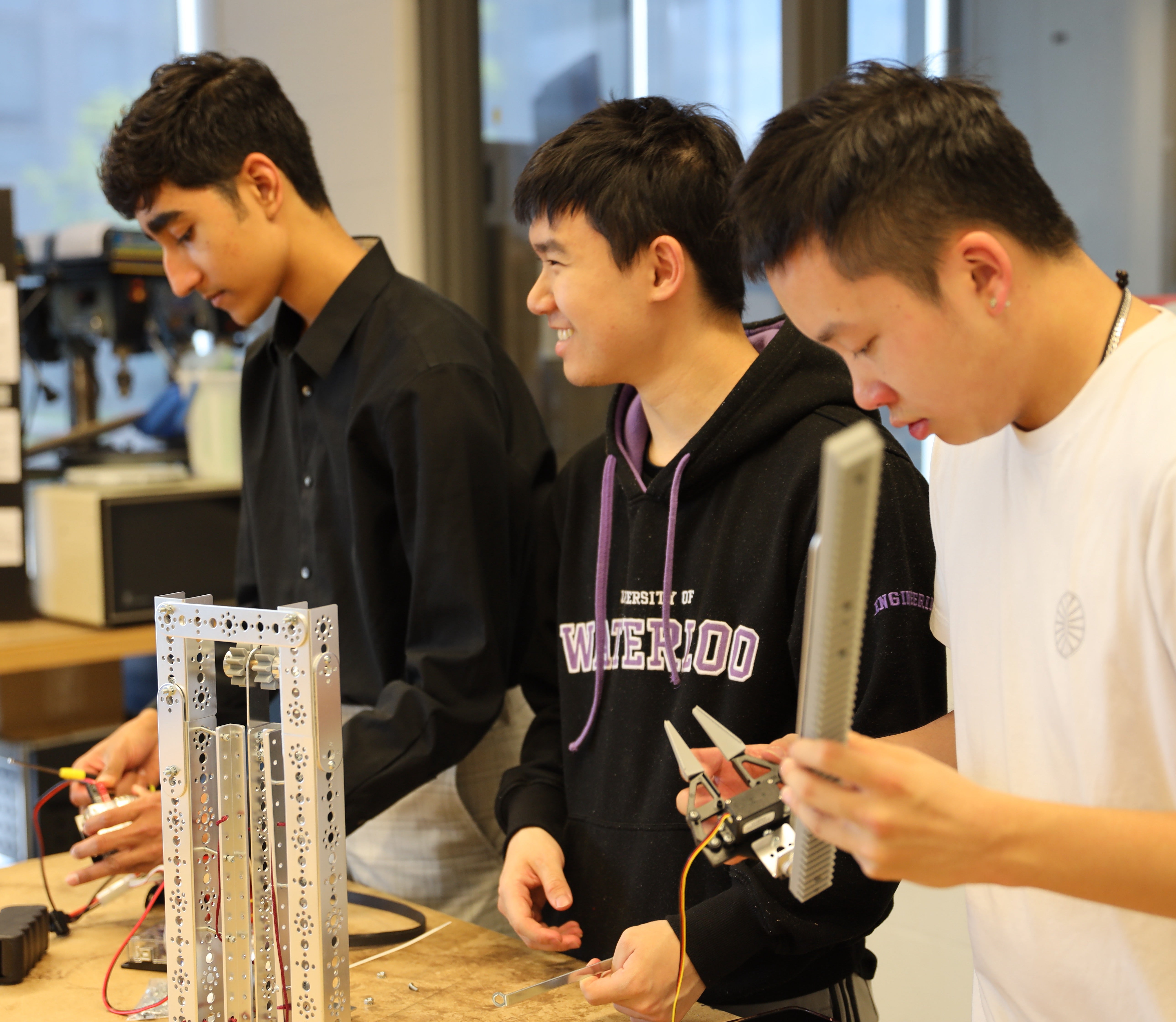

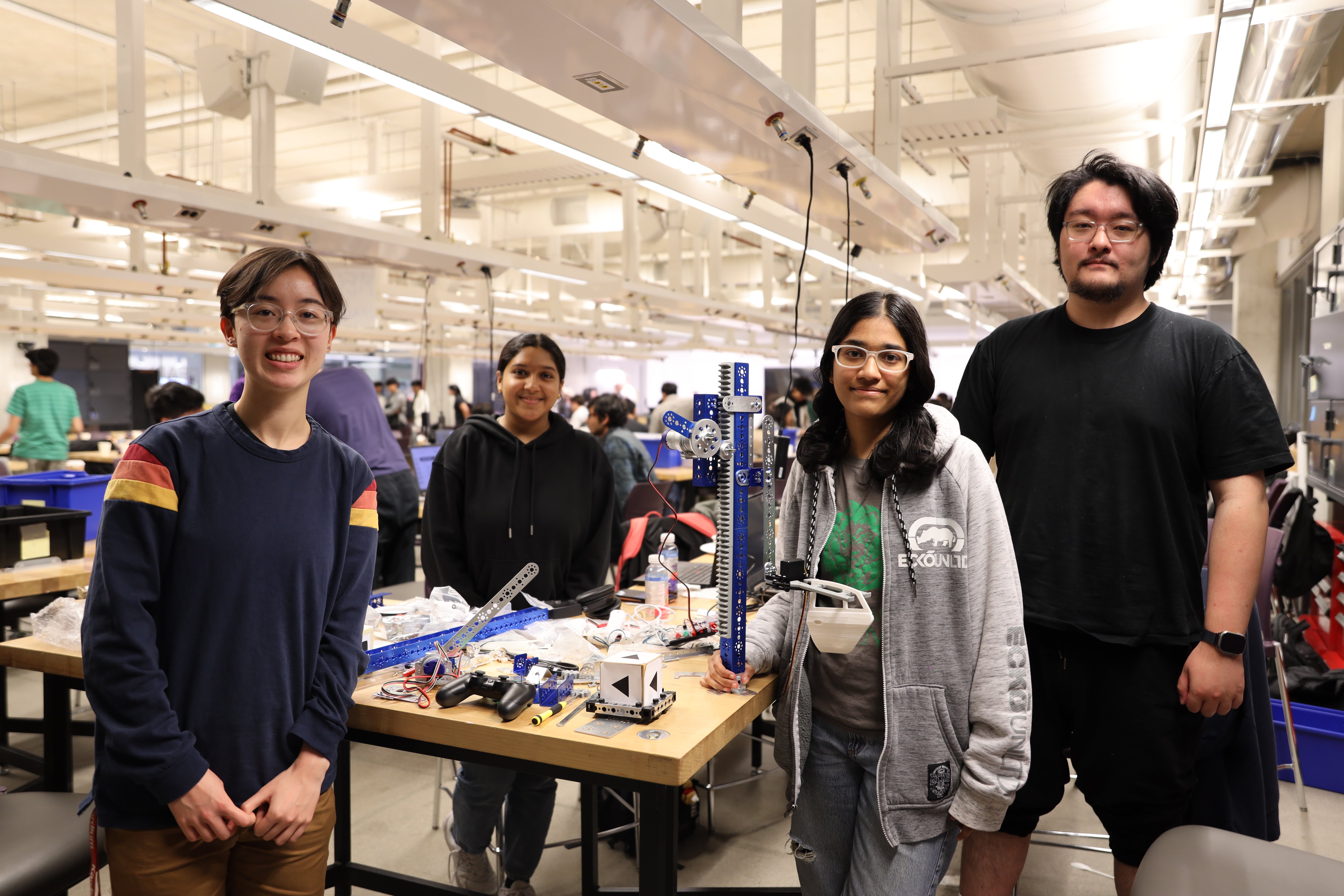

With tools and equipment provided, including access to 3D printers to generate custom parts, students wrote control software and created innovative mechanized systems that could move parts like car doors from one rack to another or boxes from a pallet to a shelf. The participants also experienced the joys and stresses of teamwork as they worked to a deadline, reviewing, revising and reiterating their designs for optimum performance.

“We had to be comfortable taking apart what we built and starting again,” said one participant. “Designing isn’t linear—we brainstorm, we test and we pivot.”

Educating engineers for the workplace

Five years ago, TMMC became the Ideas Clinic’s first industry partner to sponsor an innovation challenge. To mark this year’s event, TMMC General Manager Erin Buchanan—a Waterloo Engineering alum—announced Toyota’s renewed commitment for a further two years with a $100,000 donation.

“Supporting the Ideas Clinic reflects our commitment to fostering innovation, collaboration and industry-ready skills development,” Buchanan said. “We’re always on the lookout for top talent and the students who shine are those who can apply their classroom knowledge to real-world challenges.”

Buchanan, who was recently recognized among the 2025 Automotive News 100 Leading Women in the North American Auto Industry, also shared her professional journey, tracing her current success to the Waterloo co-op placement that launched her successful career in automotive manufacturing.

After leading major automotive manufacturing divisions across North America—including with a GM-Toyota joint venture in California—she eventually returned to Canada to take on a senior leadership role with Toyota.

“The Ideas Clinic wasn’t around in my time but, thanks to my co-op experience, I had more than a degree in chemical engineering,” Buchanan told students. “I’d experienced real workplace demands and the importance of building relationships. That you chose to spend your weekend here at the innovation challenge means you’re already shaping your futures with intent.”

Erin Buchanan, TMMC general manager and Waterloo Engineering alum, presents the Ideas Clinic with $100,000 in renewed industry support.

Learning beyond the textbook

The Ideas Clinic is a unique experiential learning facility dedicated to encouraging students to apply their classroom learning to real-world problems, have fun together and tinker—without the pressure of grading.

Dr. Sanjeev Bedi, founding director of the Ideas Clinic and a professor of mechanical and mechatronics engineering, noted that removing grades was a deliberate choice.

“Marks can make students risk averse,” Bedi said. “Here, they are free to experiment, fail and try again. That’s where the real learning happens.”

Get in touch with Silas Ifeanyi the engineering educational developer at the Pearl Sullivan Engineering IDEAs Clinic at the University of Waterloo, to find out how you can support and participate in upcoming interdisciplinary workshops and innovation challenges designed to improve educational outcomes.