MEET OUR MME FACULTY AND GRADUATE STUDENTS

What have our students accomplished?

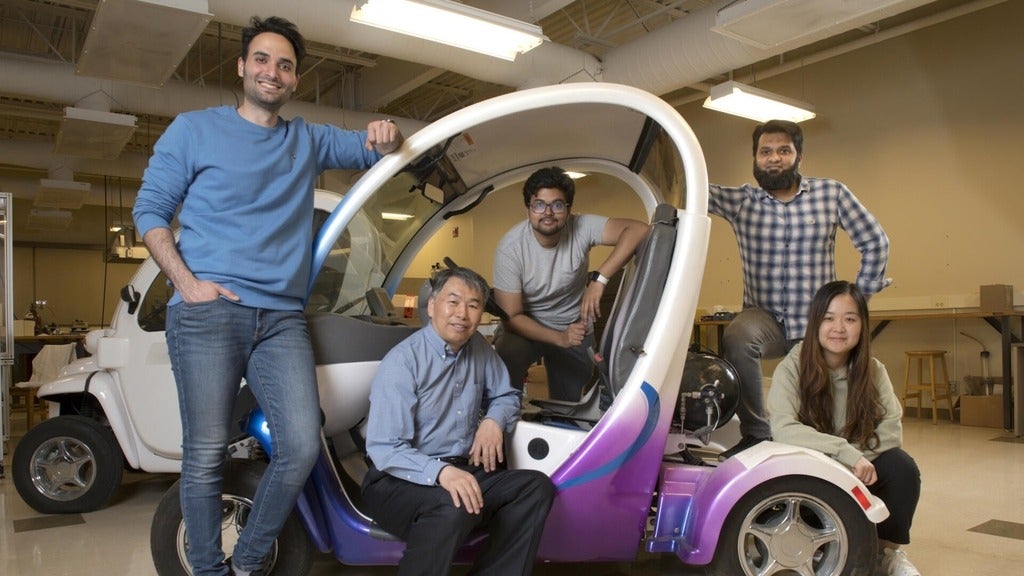

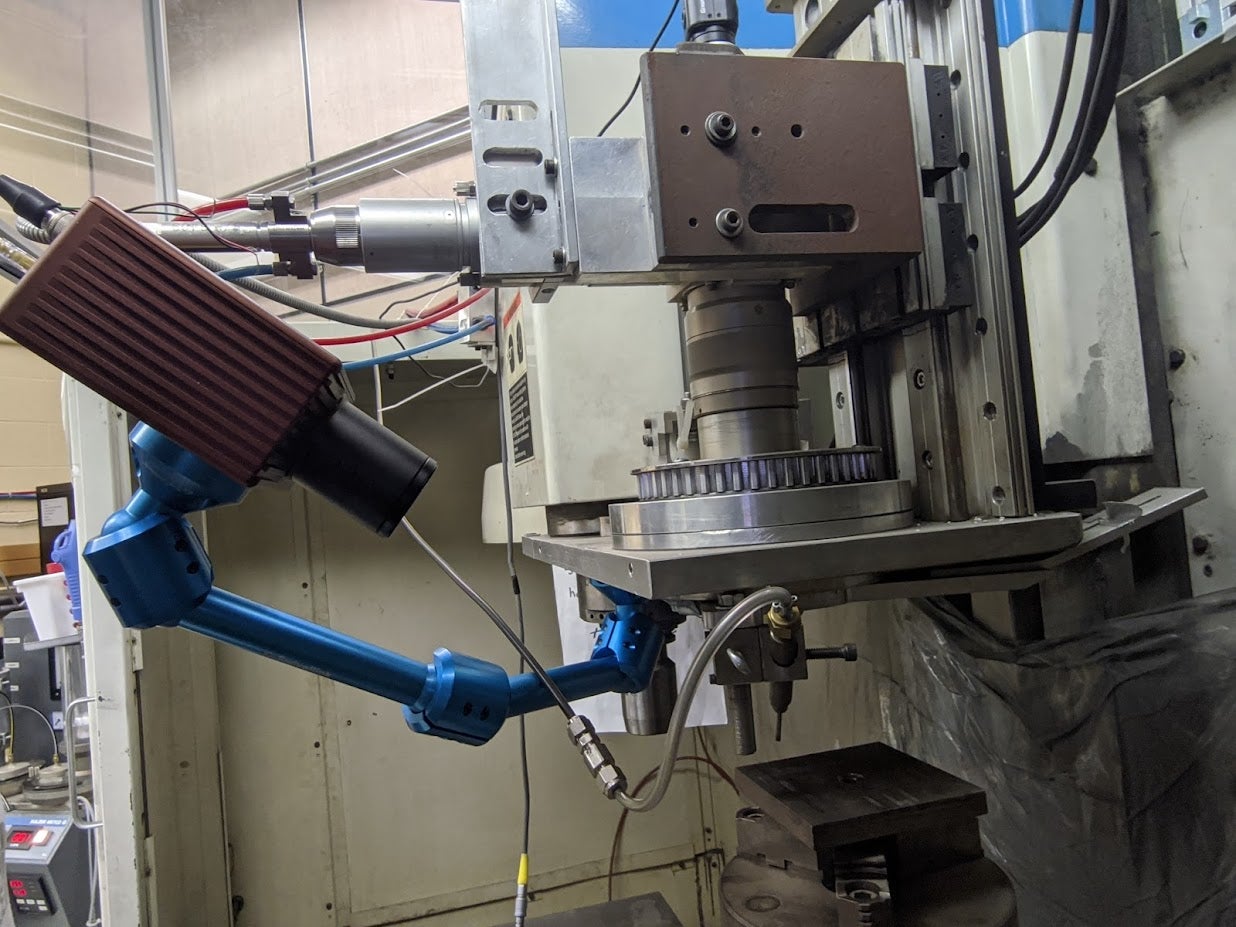

Meet Thomas Parent (MEng)

Meet Lucas Botelho (PhD)

Meet Mujtaba Ahmad (MEng)

Meet Martine McGregor (PhD)

Meet Ramin Chitsaz Dehaghani (MASc)

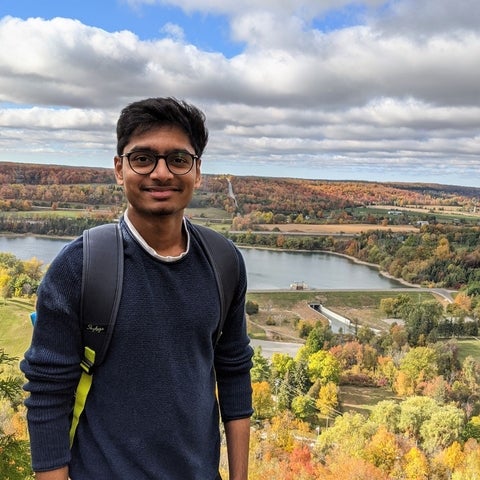

Meet Yashesh Dasari (MEng)