Nanotechnology and 3D printing came together in the development of a tough, flexible sensor for wearable devices.

Created by researchers at Waterloo Engineering, the new technology combines silicone rubber and ultra-thin layers of graphene in a material that generates electrical signals when it is bent or moved.

“Silicone gives us the flexibility and durability required for biomonitoring applications, and the added, embedded graphene makes it an effective sensor,” said Ehsan Toyserkani, a mechanical and mechatronics engineering professor who is research director at the Multi-Scale Additive Manufacturing (MSAM) Lab. “It’s all together in a single part.”

Click here for the full story.

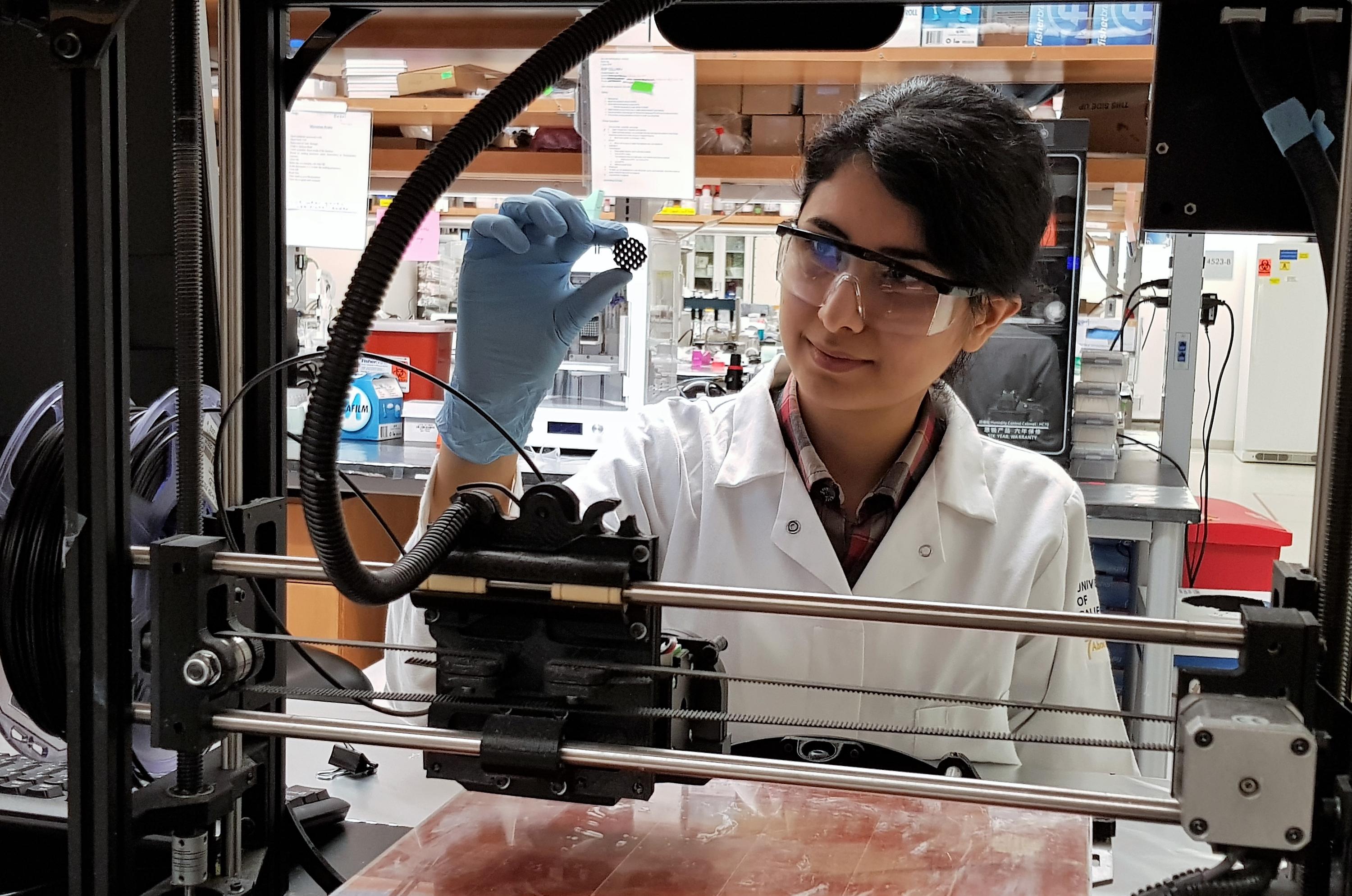

Elham Davoodi, a PhD student at Waterloo Engineering, led a project to create a new sensor material.