A student design team shared new insights on microgravity soldering at the International Astronautical Congress (IAC), presenting one of the first student-led investigations into improving electronic repair and manufacturing in space.

Building on a Waterloo-developed experiment that flew in Canada’s national microgravity research competition, the Waterloo Space Soldering Team (WSST) — a precursor to the Sedra Student Design Centre's current Waterloo Research Space Team — reported new findings on how rotational acceleration can strengthen solder joints formed in reduced gravity.

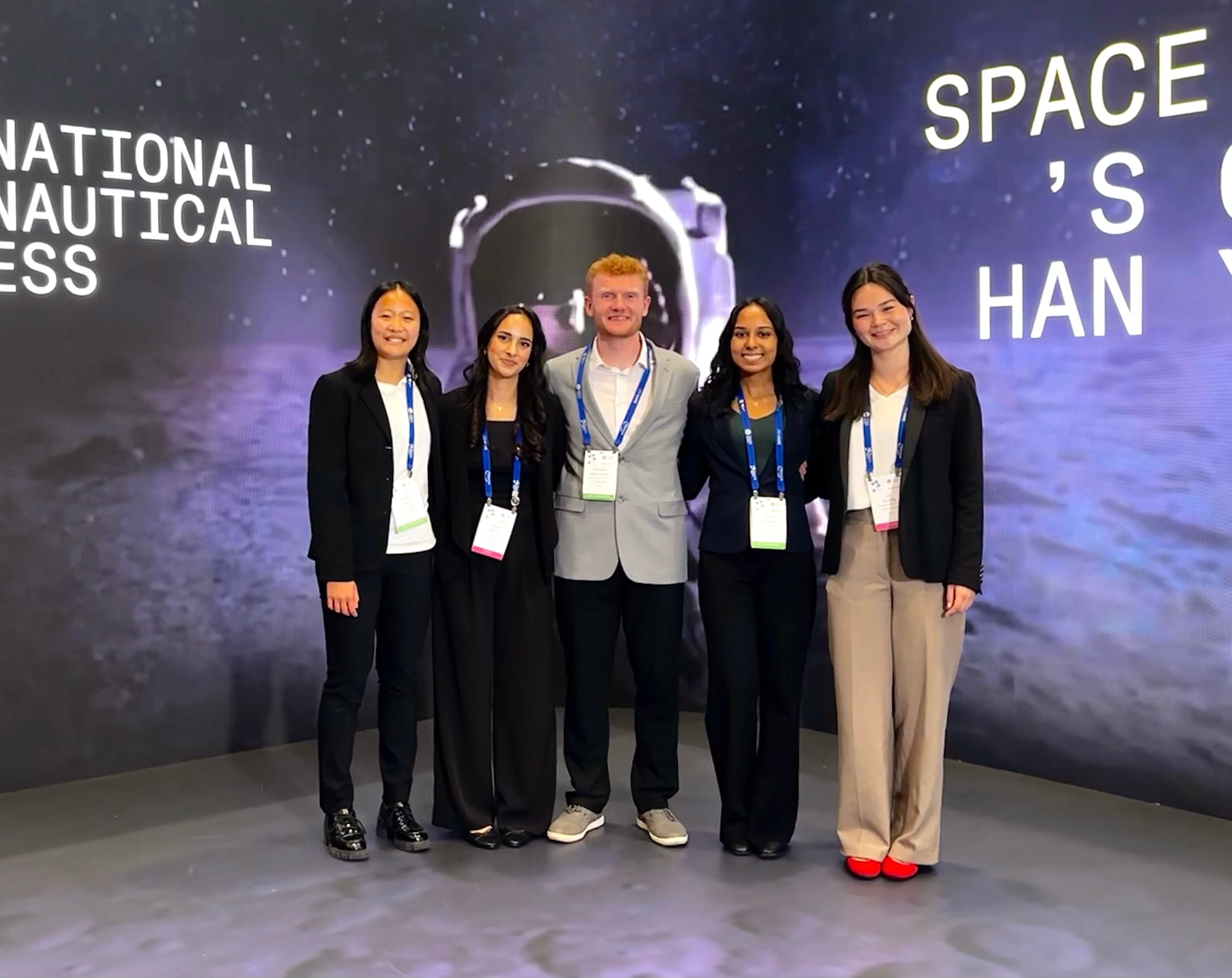

Travelling to Sydney, Australia, the student team shared their work with researchers, industry leaders and students from more than 80 countries. Their IAC paper explained how spinning a small module in microgravity could make soldering more reliable, helping reduce tiny air pockets in the metal. The team said this approach could one day make it easier to repair or build electronics during long missions in space.

From concept to flight

For the team, the opportunity to present at IAC was a milestone that grew from a year of hands-on design and rapid technical development. WSST originally formed to participate in the Canadian Reduced Gravity Experiment Design Challenge (CAN-RGX), where undergraduate teams designed, built and tested scientific payloads aboard the National Research Council’s Falcon 20 aircraft in partnership with the Canadian Space Agency. The Waterloo group earned the competition’s Overall Excellence Award after successfully flying its soldering experiment in 2024.

Their payload tested whether a centrifuge could recreate Earth-like gravitational effects during 20 to 30-second intervals of microgravity. Over two flights and 16 parabolic manoeuvres, the team collected 790 solder samples, far exceeding early expectations.

That hands-on foundation set the stage for the work the students later shared in Sydney. “It was really special to share what we’ve built through the Waterloo Space Soldering Team and see how our student-led research resonated with others,” said systems design engineering student Mysha Hamid, who also took part in the International Space Education Board program at IAC. “It made me realize how unique Waterloo’s design team culture is and how much independence and trust we’re given to take an idea from concept to flight.”

Advancing research for future missions

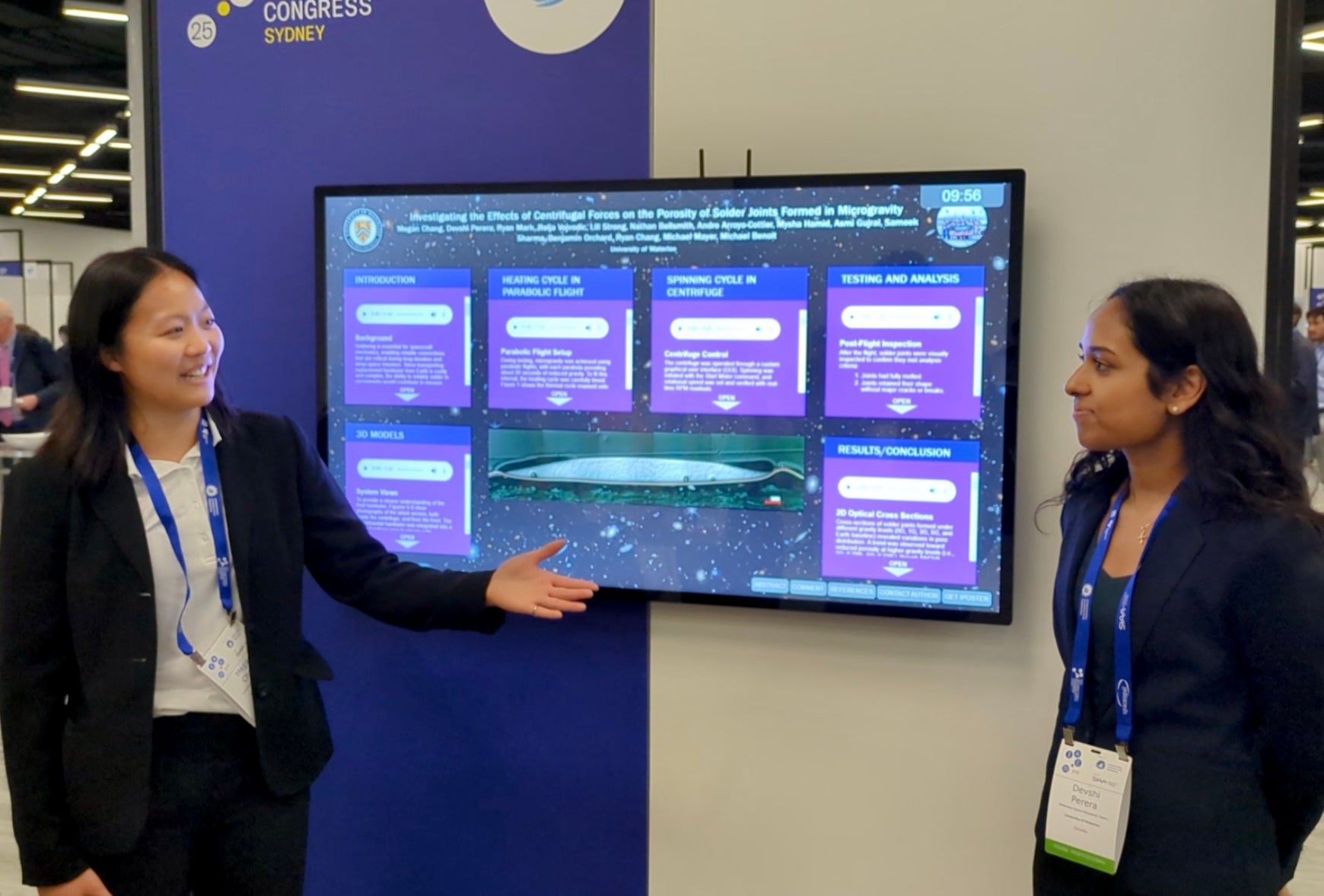

The team’s study, Investigating the Effects of Centrifugal Forces on the Porosity of Solder Joints Formed in Microgravity, detailed how centrifugal force can decrease void formation, a key factor influencing the reliability of electronics assembled in space. Improved in-orbit repair and fabrication techniques could reduce mission costs, extend spacecraft lifespan and make long-duration operations more feasible.

The paper’s author list includes Dr. Michael Mayer and Dr. Michael Benoit, professors of mechanical and mechatronics engineering, and Waterloo Engineering students Megan Chang, Devshi Perera, Ryan Mark, Relja Vojvodic, Lili Strong, Nathan Bellsmith, Andre Arroyo-Cottier, Mysha Hamid, Asmi Gujral, Sameek Sharma, Ben Orchard and Ryan Chang.

For WSST, presenting at IAC marked another step forward in a project that began with a small team and an ambitious idea. What started as a CAN-RGX proposal in 2023 has grown into an internationally recognized student-led effort contributing to the future of in-space manufacturing.

Go to Waterloo students win microgravity research competition in Quebec and Student experiment takes flight on Canadian Space Agency Balloon for additional stories on the Waterloo Research Space and Waterloo Space Soldering teams.

Go to Investigating the effects of centrifugal forces on the porosity of solder joints formed in microgravity to explore their full IAC presentation.